16 GC

The Cat® 16 GC Motor Grader is easy to operate and maintain. Control the blade with consistent precision using the steering wheel and lever controls from the comfort of the cab. An on-demand fan and standard ECO mode reduces fuel consumption while easy access to maintenance points makes service quick and simple.

Net Power - ISO 9249/SAE J1349

334 HP

Engine Model

Cat® C13

Emissions

Equivalent to U.S. EPA Tier 3/EU Stage IIIA

Specification

Value

Net Power - ISO 9249/SAE J1349

334 HP

Engine Model

Cat® C13

Emissions

Equivalent to U.S. EPA Tier 3/EU Stage IIIA

Displacement

763 in³

Bore

5.1 in

Stroke

6.2 in

Torque Rise - ISO 9294

46%

Maximum Torque

1,282 lb/ft

High - Ambient Capability

122 °F

Number of Cylinders

6

Note (1)

Net power is tested per ISO 9249, SAE J1349, and EEC 80/1269 standards in effect at the time of manufacture.

Note (2)

Net power advertised is the power available at rated speed of 2,000 rpm, measured at the flywheel when engine is equipped with fan, air cleaner, muffler and alternator.

Note (3)

Power as declared per ISO 14396.

Specification

Value

Weight*

70,127 lb

Note

Typically equipped machine weight is calculated with full fluids, 4.9 m (16 ft) blade, push plate, ripper, bottom guard, and operator.

Specification

Value

Height - Top of Cab

139.3 in

Length of Machine*

463.8 in

Width

130.7 in

Note

Typically equipped with push block and ripper.

Specification

Value

Blade Width

16 ft

Blade Height

31 in

Arc Radius

16.3 in

End Bit - Width

6 in

Throat Clearance

5 in

Specification

Value

Circle Center Shift Left

27.2 in

Circle Center Shift Right

22 in

Moldboard Side Shift Left

29.1 in

Moldboard Side Shift Right

31.1 in

Maximum Depth of Cut

18.5 in

Maximum Lift Above Ground

15.7 in

Blade Tip Range Forward

40°

Blade Tip Range Backward

5°

Specification

Value

Fuel Tank

114 gal (US)

Cooling System

18.2 gal (US)

Engine Crankcase

9.5 gal (US)

Circle Drive

2.6 gal (US)

Hydraulic System

14.8 gal (US)

Transmission and Differential

30.9 gal (US)

- Get the reliable power you need to get the job done with the Cat C13 engine.

- The machine is well-balanced to help you get full drawbar power to the ground.

- Increase your fuel economy up to 5% with the standard ECO mode.

- The on-demand fan reduces fuel consumption and under-hood heat for longer component life.

- The powershift transmission provides smooth shifting and has the capability to make quick directional changes when utilizing the new ergonomic shifter. With eight forward and six reverse speeds, you can select the right gear for the job.

- Improve productivity with the Electronic Throttle Control which matches engine power and torque to application requirements.

- The efficient hydraulic system helps you to create a more precise and consistent grade.

- The Digital Blade Slope Meter option shows you the grade without relying on manual grade checkers.

- Get extra traction with the differential lock when working in loose material.

- Keep your machine’s engine speed at your desired level when using throttle lock and throttle hold.

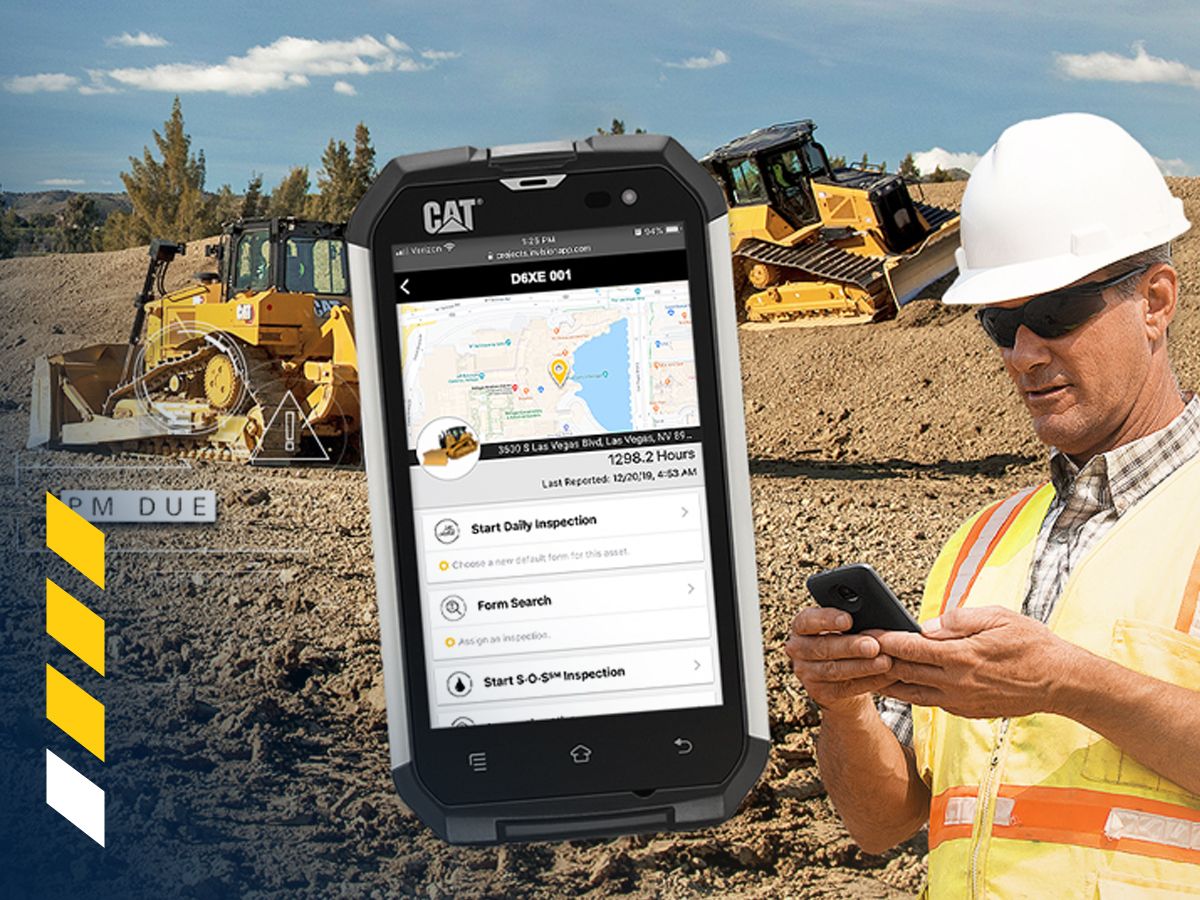

- Product Link™ Elite provides location, machine hours, fuel usage, productivity, idle time, diagnostic codes, and other machine data on demand through the VisionLink® online interface, which helps you improve jobsite efficiency with lower operating costs. Minestar™ can also be configured to your machine for added support.

- Choose your comfort level in the cab with the mechanical suspension or air suspension seat.

- Easily pull the control console and tilt the steering wheel to your ideal position.

- The standard Heating, Ventilation and Air Conditioning (HVAC) system circulates fresh air, prevents dust entry, and keeps windows from fogging.

- Standard fresh air vents at the rear of the cab help to keep the windows clear.

- Easily add a radio to the cab using the standard mount, speakers and wiring.

- Neatly pack away all your gear with in-cab storage space, cup and cell phone holder.

- The adjustable drawbar circle moldboard helps to stay factory tight with shimmable draftball, circle and blade wearstrips and to provide precision grading pass after pass.

- The machine is built for a long life with reinforced structures.

- The standard slip clutch protects the circle drive if the moldboard strikes an immovable object.

- The front axle maximizes bearing life while also minimizing maintenance with the live spindle design.

- The standard compression brakes help to extend the brakes life while also maintaining the machine’s braking power.

- Standard blade lift accumulators help to absorb impact loads from the moldboard and help protect the ground engagement tools and front frame from potential damage.

- See what’s behind you with the high-resolution rear camera option. The dedicated display can always be on to ensure a safe work environment.

- In the event of a drop in hydraulic pressure, count on the secondary steering system option to help stop the machine safely.

- Use three points of contact when entering and exiting the machine with strategically placed walkways and grab rails. An optional rear step is available to help with access to the tandems. The steps use an anti-skid punch plate to prevent slipping.

- Ground level engine shut-off switch stops all fuel to the engine when activated and shuts the machine down.

- See the rear of your machine with side and rearview mirrors.

- Work past sundown using the strategically placed lights for nighttime visibility.

- Filters are grouped together for easy access and preventative maintenance.

- The standard drawbar circle moldboard increases durability using hardened circle teeth and replaceable wear inserts to help sustain factory tightness.

- Split shims are added for easier service and adjustments for the ball and socket.

- Reduce daily greasing requirements and potential costly repairs to critical joints with the optional autolube system.

- Delayed engine shutdown allows for proper cooling of the engine which helps to prolong component life.

- Brake adjustments are easily accessible and offer an indicator when service is needed.

- Add the optional under hood lighting to illuminate daily maintenance points.

- An optional ground level fast fill system is available to speed up fuel stops.

- Improve the performance and efficiency of your machine with the optional push block.

- Optional rippers are available to assist with grading hard ground.

- Make your machine fire suppression ready with the optional dealer installed kit.

- Optional guarding protects your machine from damage in demanding applications. The optional bottom guard shields the transmission and filter. Optional front axle guards help to protect the front axle and steering cylinders.