785

The 785 Large Mining Truck was Caterpillar’s first entry into the mining industry more than three decades ago and has been a proven performer on sites around the world ever since. And now it’s the first to combine a game-changing level of efficiency with industry-leading physical availability to deliver the next generation of productive hauling. It all starts with the operator, who sits in a state-of-the-art environment designed for efficiency and equipped with features that increase comfort, automate functions, provide real-time information and boost confidence. The 785 also delivers significant improvements in serviceability and reliability, enhanced connectivity and easier technology integration. These improvements — and more — take an already proven truck to the next level of productivity.

Gross Power - SAE J1995

1600 HP

Net Power - SAE J1349

1509 HP

Engine Model

Cat® 3512E

Specification

Value

Gross Power - SAE J1995

1600 HP

Net Power - SAE J1349

1509 HP

Engine Model

Cat® 3512E

Emissions Rating

Fuel Optimized

Bore

6.7 in

Stroke

8.5 in

Displacement

3573 in³

Note (1)

Net Power advertised is the power available at the flywheel when the engine is equipped with air intake system, exhaust system, and alternator.

Note (2)

U.S. EPA Tier 4 Final / EU Stage V available for applicable markets.

Note (3)

Additional fuel optimized selectable power ratings: 1,450 hp

Specification

Value

Nominal Rated Payload (33.00R51 Tires)

153 ton (US)

Rated Gross Machine Weight (33.00R51 tires)

550000 lb

Nominal Rated Payload (36.00R51 Tires)

157 ton (US)

Rated Gross Machine Weight (36.00R51 tires)

564000 lb

Chassis Weight (33.00R51 Tires)

186799 lb

Chassis Weight (36.00R51 Tires)

193192 lb

Body Weight

57779 lb

Note (1)

Consult your tire manufacturer for maximum tire load

Note (2)

Chassis weight with full fuel and fluids, standard & mandatory attachments, hoist, body mounting group, rims, and tires.

Note (3)

Body weight varies depending on body selection and configuration.

Specification

Value

Front Axle - Empty

48%

Rear Axle - Empty

52%

Front Axle - Loaded

33%

Rear Axle - Loaded

67%

Note

Weight distributions optimized with Cat body.

Specification

Value

Type

Double reduction, planetary with full floating axles.

Differential Ratio

2:10:01

Planetary Ratio

10.83:1

Total Reduction Ratio

22.75:1

Specification

Value

Forward - 1

7.5 mile/h

Forward - 2

10.2 mile/h

Forward - 3

13.8 mile/h

Forward - 4

18.6 mile/h

Forward - 5

25.2 mile/h

Forward - 6

34 mile/h

Reverse

6.8 mile/h

Top Speed - Loaded

34 mile/h

Note

Maximum travel speeds with standard 33.00-R51 tires.

Specification

Value

Standard Tire

33.00R51

Optional Tire

36.00R51

Rims

610 mm (24") Rims (standard). 660 mm (26") Rims (optional).

Note (1)

Quick Change Rims optional.

Note (2)

Caterpillar recommends the customer evaluate all job conditions and consult tire manufacturer for proper tire selection and TKPH (TMPH) capabilities.

Specification

Value

Service Brakes

Four-Corner, Wet Disc, Oil Cooled, Hydraulically Actuated

Front Wet Disc Brake Surface Area

9487 in²

Rear - Wet Disc Brake Surface Area

13908 in²

Standards

Service and Secondary: ISO 3450:2011

Parking Brake

Four corner, multi disc, spring applied, hydraulically released

Specification

Value

Struck

72 m^3 / 94 yd^3

Heaped (SAE 2:1)

99 m^3 / 129 yd^3

Note

Consult your local Cat dealer for body recommendations.

Specification

Value

Type

Twin, two-stage hydraulic cylinders with snubbing valve.

Pump Flow - High Idle

192.7 gal/min

Relief Valve Setting - Raise

2500 psi

Body Raise Time - High Idle

15.2 s

Body Lower Time - Float High Idle

15.9 s

Body Lower Time - Float Low Idle

16.2 s

Body Power Down- High Idle

15.9 s

Specification

Value

Type

Self-contained nitrogen/oil cylinders, pin-to-pin mounting, top & bottom double shear clevis attachments

Effective Cylinder Stroke - Front

12.6 in

Effective Cylinder Stroke - Rear

6.5 in

Rear axle - Oscillation

+/- 5 degrees

Specification

Value

Fuel Tank

410 gal (US)

Diesel Exhaust Fluid Tank

36 gal (US)

Cooling System

100 gal (US)

Crankcase

54 gal (US)

Front Wheels - Each

8 gal (US)

Differential - Final Drives

139 gal (US)

Steering Tank

29 gal (US)

Steering System - Includes Tank

45 gal (US)

Brake/Hoist Tank

135 gal (US)

Brake Hoist System - Includes Tank

160 gal (US)

Torque Converter - Transmission System - Including Sump

46 gal (US)

Specification

Value

Air Conditioning

HFC - 134A refrigerant: 24,500 Btu/h

Heater / Defroster

33300 Btu/h

Note

The operator sound pressure level, 77 dB(A) with direct drive and 75 dB9A) with optional clutch, tested to ISO 6396:2008.

ROPS Standards (1)

ROPS (Rollover Protective Structure) meets ISO 3471:2008 for Operator and ISO 13459:2012 for Trainer.

FOPS Standards

FOPS (Falling Objects Protective Structure) meets ISO 3449:2005 Level II for Operator and ISO 13459:2012 Level II for Trainer.

Specification

Value

Steer Angle

36 °

Turning Diameter - ISO 7457:1997 (33.00R51 tires)

97.75 ft

Steering Standards

ISO 5010:2007

Specification

Value

Height - Top of ROPS

17.09 ft

Overall Body Length

39.32 ft

Inside Body Length

27.29 ft

Overall Length

39.23 ft

Wheel Base

17 ft

Rear Axle - Tail

12.56 ft

Ground Clearance

3.29 ft

Dump Clearance

3.7 ft

Loading Height - Empty

17.39 ft

Inside Body Depth - Maximum

9.15 ft

Overall Height - Body Raised

39.48 ft

Operating Width

24.72 ft

Centerline Front Tire Width

15.91 ft

Engine Guard Clearance

3.41 ft

Overall Canopy Width

24.81 ft

Outside Body Width

22 ft

Inside Body Width

19.72 ft

Front Canopy Height

19.8 ft

Rear Axle - Clearance

3.25 ft

Centerline of Rear Dual Tire Width

14.06 ft

Overall Tire Width

20.59 ft

- The Advanced Power Electronic Control Strategy (APECS) enables faster cycle times thanks to more continuous torque and rimpull.

- Forward momentum and torque are maintained through each shift, with optimum gear selection resulting in faster acceleration.

- The 785 delivers a 6% higher TKPH /TMPH (tonne-kilometer-per-hour / ton-mile-per-hour) thanks to larger tire options that allow allow mines to take advantage of higher speeds, particularly in flat, long-haul, high-speed applications.

- Productivity-enhancing features such as Hill Start Assist with Anti-Rollback, Enhanced Traction Control, Dynamic Stability Control (DSC), Anti-lock Brake System (ABS), Machine Speed Limiting and Cruise Control improve machine responsiveness and controllability while improving cycle times and reducing operator fatigue.

- Wide, slip-resistant surfaces and hand rails, plus an optional powered access ladder, improve access and egress.

- Superior control is delivered by a patented braking system that provides immediate, fade-resistant braking and retarding.

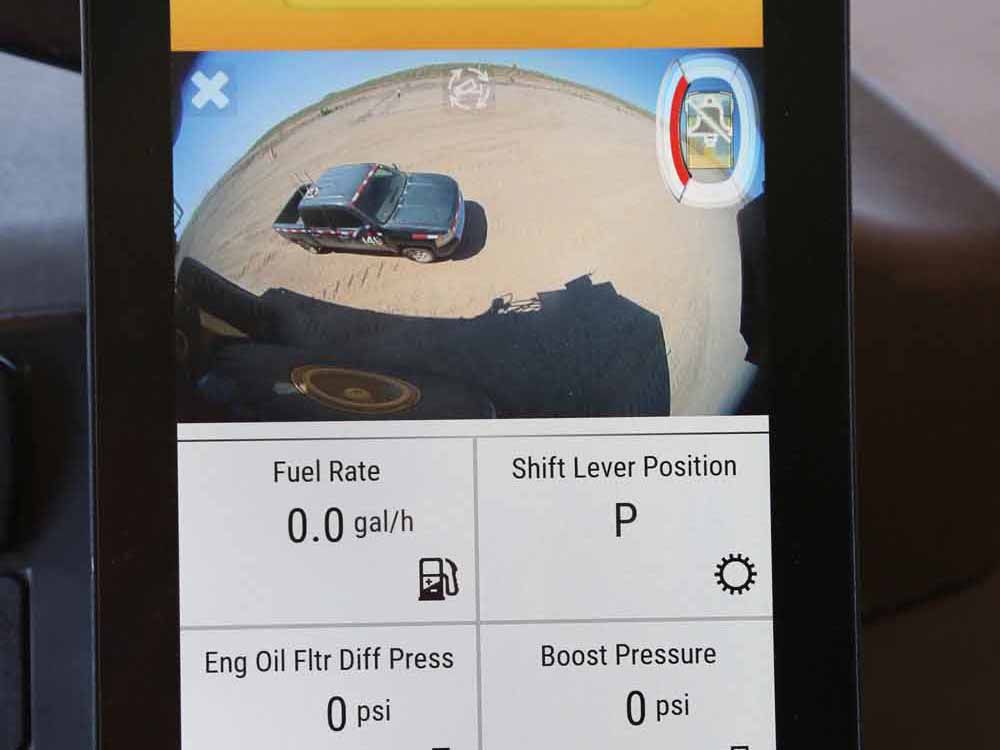

- Visibility is enhanced by an optional 360-degree Surround View camera, which offers a bird’s-eye view.

- The Cat MineStar™ Object Detection system combines radar and camera systems to warn operators about light vehicles or stationary hazards within the immediate vicinity of their machines.

- The optional Driver Safety System alerts the operator if fatigue or distraction are detected.

- The cab provides 34% more operator space than D-Series models. It’s 17% wider and offers 11% more legroom and 19% more shoulder room. Controls, levers and switches are positioned for ease of use.

- With 40% less Sound Pressure Level (SPL), automated temperature control and cab filtration, operators enjoy a safer and more comfortable environment.

- A walkthrough cab with fully adjustable center console, easy-to-adjust seat and increased leg room makes the cab ideal for operators of all sizes.

- The next generation seat is four-point-restraint ready and incorporates features like thigh tilt and extensions, air adjustable side and lumbar bolsters, and heated and cooled cushions.

- Operators enjoy a more comfortable ride thanks to smoother transitional shifting and reduced shift jerk levels provided by APECS controls.

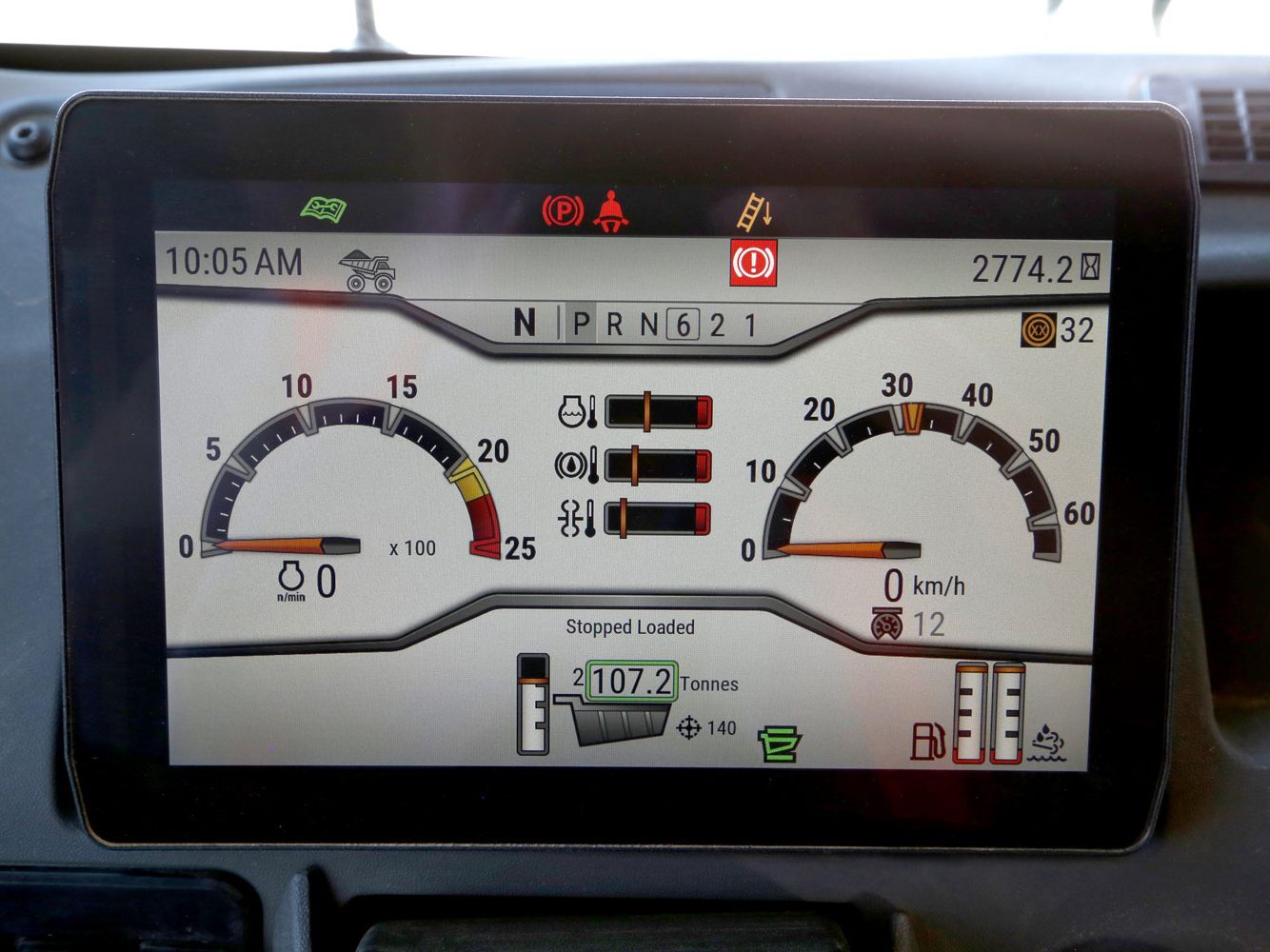

- Higher resolution displays improve access to information. Machine data, controls and guidance information are consolidated onto two ideally located 10-inch screens.

- The optional Auto Hoist feature automatically raises the body and controls engine speed, simplifying operation and minimizing cycle times.

- Speed coaching gives operators real-time feedback on how to operate the truck to maximize its productivity.

- The payload monitoring system comes with more accurate measurements, providing immediate feedback to the operator.

- The new modular HVAC (heating, ventilation and air conditioning) system improves reliability and consolidates components so the entire system can be removed and replaced quickly.

- A modular radiator reduces engine removal and installation time and enables rebuilds to be completed off the truck.

- New remote flash and remote troubleshooting capabilities provide immediate access to the latest software updates and make it possible to troubleshoot the machine remotely.

- Time spent on regular maintenance procedures is reduced thanks to features such as extended-interval filters with ground-level access; grouped service points and optional centralized service center; cleaner hydraulic and electrical routings; SOS and pressure ports for faster, safer oil sampling and troubleshooting; and fluid-level sight glasses.

- A 100% airless electric start option eliminates air system maintenance from the machine and improves uptime.

- Longer-life components, extended service intervals and easier maintenance deliver consistently high mechanical availability.

- A reduction in torque spikes and fewer variations in engine speed, made possible by APECS controls, deliver longer engine and powertrain component life.

- The 785 frame uses a box-section design, incorporating two forgings and 21 castings in high-stress areas with deep penetrating and continuous wrap-around welds to resist damage from twisting loads without adding extra weight. The mild steel frame provides flexibility, durability and resistance to impact loads.

- Component life is enhanced thanks to the standard rear-axle continuous filtration feature. Cleaner oil helps promote lubrication that leads to longer life

- The frame, powertrain, engine and components are built to be rebuilt — delivering multiple lives of like-new performance at a fraction-of-new price.

- Caterpillar designed and manufactured bodies are integrated with the chassis as a unit to optimize performance and incorporate optional Tier 4 components, including body exhaust heat.

- The lightweight Mine Specific Design (MSD) body is designed with built-in carryback reduction features (front wall curved transition and corner pop-out plates) and is available with optional application-specific body liners.

- Intended for tough applications, the heavy-duty Dual Slope body provides excellent load retention, maintains a low center of gravity with optimum load distribution and reduces shock loading.

- The 785 is designed to use less fuel, which reduces engine emissions, and there is zero fuel burn during retarding. The Tier 4 Final engine reduces NOx and particulate matter.

- The Cat 3512E engine’s 12-cylinder four-stroke design uses long, effective power strokes for more complete fuel combustion and optimum fuel efficiency.

- The 785 engine is compatible with diesel fuel blended with lower-carbon intensity fuels such as biofuels and renewable fuels.

- Features like oil renewal systems, continuous rear axle filtration, extended life filters and longer maintenance intervals decrease the amount of waste contributed to the environment.

- By rebuilding machines and components, the Cat Rebuild and Cat Reman programs preserve raw materials, conserve energy and reduce emissions.

- The 785 is available in a cold-weather configuration that makes it ideal for mines operating in frigid environments. It features automatic engine thermal management, a variable fan speed for low temperature operation, and an electric- or air-start option.

- The 3512E engine gives you the ability to select the power rating to match your current fleet performance or to achieve faster cycle times.

- The 23% net torque rise provides unequaled lugging force during acceleration, on steep grades and in rough underfoot conditions.

- Tire options allow you to select the tire that best matches your application, with a larger tire for flat, long, high-speed applications. The frame is designed to maintain the same turning diameter while accommodating larger tires.

- The 785 is available in two options to meet emissions standards. The optional Tier 4 Final engine meets the strictest standards while the LRC engine is available in those countries that are less regulated.

- MineStar Fleet is a fleet monitoring system that can be used to measure, manage and maximize the overall hauling operation.

- Additional MineStar Detect offerings include Awareness, which can provide warnings, and the in-cab Driver Safety System, which intervenes when it detects fatigue or distraction.

- Machine health and condition monitoring solutions enable a proactive approach to maintenance.

- Next generation connectivity delivers faster data transfers, better access to data, consistent data communication, more actionable data, improved data analytics and new diagnostic capabilities.

- The backbone of the next generation machine is 100 Mbps two-wire ethernet communication across the machine controllers, sensors that are optimized for data analytics, and robust controls.

- Advanced connectivity on the 785 truck is enabled by standard cellular 4G/LTE, optional dual mode 4G/LTE and Satellite Product Link™, or locally installed Wi-Fi.

- Every machine from the factory comes with Product Link Elite as a standard offering. This solution enables the truck to collect and transmit information into locally-hosted or cloud-hosted applications.