793F

What will it take to boost your bottom line? An engine that delivers more power and performance for an increase in productivity? A class-leading empty weight that leads to optimized payload? A longer life for high operating hours and reduced costs? The opportunity to reap the significant productivity and efficiency benefits from industry-leading automation? With the Cat® 793F Mining Truck, you get all this — and more. This popular industry workhorse is the ideal choice for a wide variety of applications. It hauls more every load, every cycle and every shift. And it delivers a better bottom line to the most important mine in the world: yours.

Gross Power - SAE J1995

2650 HP

Net Power - SAE J1349

2478 HP

Engine Model

Cat® C175-16

Specification

Value

Gross Power - SAE J1995

2650 HP

Net Power - SAE J1349

2478 HP

Engine Model

Cat® C175-16

Rated Speed

1750 r/min

Emissions

Fuel Optimized

Bore

6.9 in

Stroke

8.7 in

Displacement

5187 in³

Note (1)

Net Power advertised is the power available at the flywheel when the engine is equipped with air intake system, exhaust system, and alternator.

Note (2)

EPA Tier 4 Final / EU Stage V available for applicable markets.

Specification

Value

Rated Gross Machine Weight

851000 lb

Chassis Weight

265639 lb

Body Weight

67682 lb

Note (1)

Consult your tire manufacturer for maximum tire load

Note (2)

Chassis weight with full fuel and fluids, standard & mandatory attachments, hoist, body mounting group, rims, and tires.

Note (3)

Refer to the Cat Mining Truck 10/10/20 Overload Policy for maximum gross machine weight limitations.

Nominal Rated Payload

256 ton (US)

Specification

Value

Differential Ratio

1.8:1

Planetary Ratio

16:01

Total Reduction Ratio

26.8:1

Specification

Value

Forward - 1

8 mile/h

Forward - 2

10.8 mile/h

Forward - 3

14.8 mile/h

Forward - 4

19.9 mile/h

Forward - 5

27.1 mile/h

Forward - 6

37.3 mile/h

Reverse

7.3 mile/h

Top Speed - Loaded

37.3 mile/h

Specification

Value

Standard Tires

40.00 R57

Rims

29" or 32"

Note

Quick Change Rims optional.

Note (1)

Extended life wheel stations optional.

Note (2)

Caterpillar recommends the customer evaluate all job conditions and consult tire manufacturer for proper tire selection and TKPH (TMPH) capabilities.

Specification

Value

Type

Self-contained nitrogen/oil cylinders, pin-to-pin mounting, top & bottom double shear clevis attachments

Effective Cylinder Stroke - Front

5.1 in

Effective Cylinder Stroke - Rear

4.2 in

Rear axle - Oscillation

±4.9 degrees

Specification

Value

Service Brakes

Four-Corner, Wet Disc, Oil Cooled, Hydraulically Actuated

Front Wet Disc Brake Surface Area

13921 in³

Rear - Wet Disc Brake Surface Area

20,847 in³

Standards

(Service and Secondary): ISO 3450:1996

Parking Brakes

Four-corner, Multi-disc, Spring Applied, Hydraulically Released

Load Brake

Rear service brakes

Note

Anti-Lock Brake System (ABS) optional with CMD package

Specification

Value

Type

Twin, two-stage hydraulic cylinders with snubbing valve

Pump Flow - High Idle

224 gal/min

Relief Valve Setting - Raise

2955 psi

Body Raise Time - High Idle

19 s

Body Lower Time - Float

20 s

Body Power Down - High Idle

17.5 s

Specification

Value

Brake Surface - Front

13921 in²

Brake Surface - Rear

20847 in²

Standards

J-ISO 3450 JAN88, ISO 3450:1996

Specification

Value

Air Conditioning

Air Conditioning (HFC - 134A refrigerant): 24,300 Btu/hr

Heater / Defroster

38900 Btu/h

Note

Ambient capabilities down to -30C (-22F) for heater/defroster and up to 50C (122F) for air conditioning.

ROPS Standards (1)

The operator sound pressure level, 76 dB(A), complies with ISO 6394 and ISO 6396.

ROPS Standards (2)

ROPS (Rollover Protective Structure) meets ISO 3471:1994 criteria.

FOPS Standards

FOPS (Falling Objects Protective Structure) meets ISO 3449:1992 Level II criteria.

Specification

Value

Front Axle - Empty

48 %

Rear Axle - Empty

52 %

Front Axle - Loaded

33 %

Rear Axle - Loaded

67 %

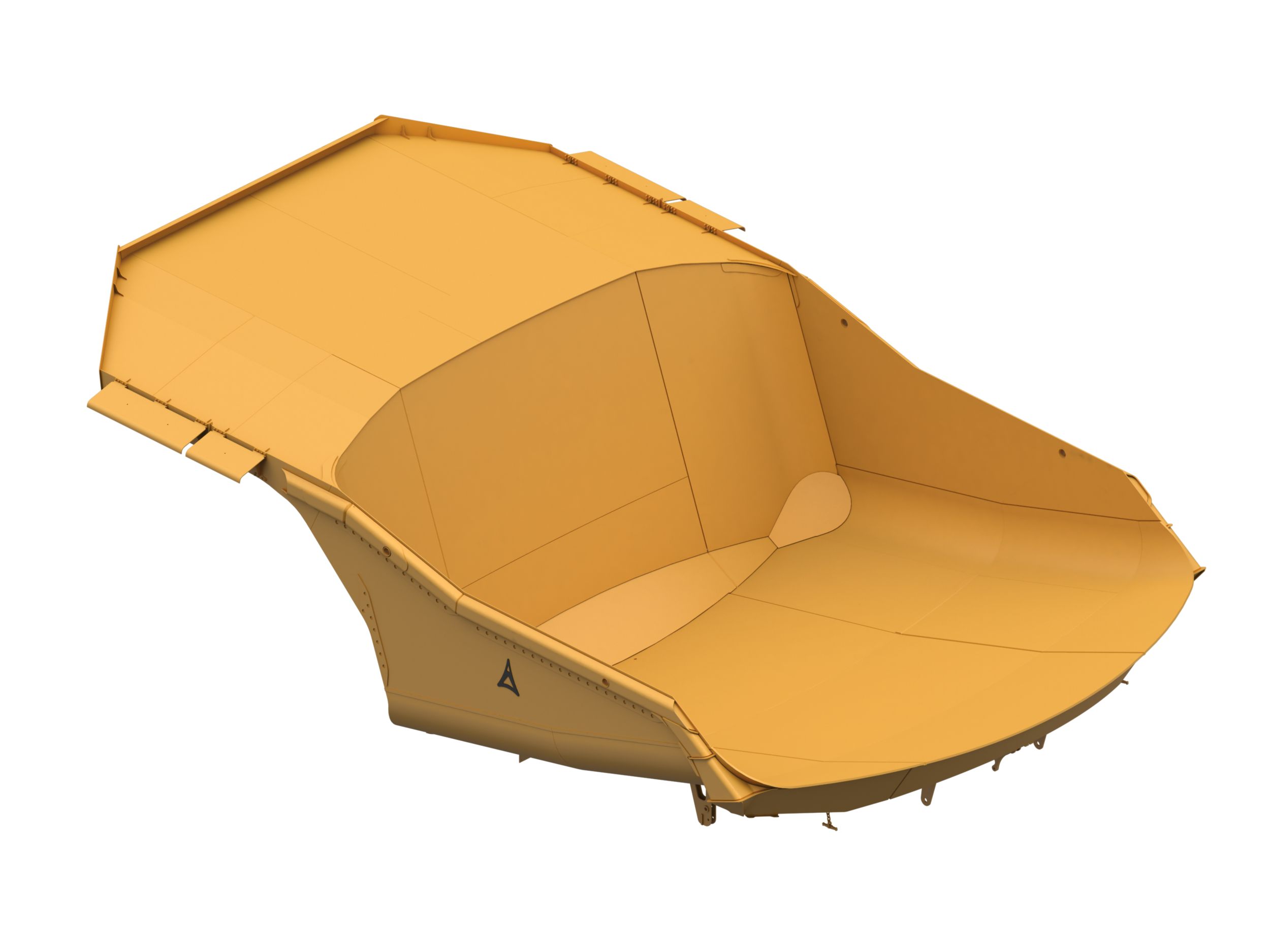

Specification

Value

Struck

112-142 m³ (146-186 yd³)

Heaped (SAE 2:1)

159-190 m3 (209-250 yd3)

Note

Contact your local Cat dealer for body recommendation.

Specification

Value

Fuel Tank

750 gal (US)

Fuel Tank - Optional

1300 gal (US)

Diesel Exhaust Fluid Tank

62 gal (US)

Cooling System

284 gal (US)

Crankcase

82 gal (US)

Rear Axle - Housing

260 gal (US)

Steering System - Including Tank

77 gal (US)

Brake Hoist System - Includes Tank

347 gal (US)

Torque Converter - Transmission Sump

27 gal (US)

Torque Converter/Transmission System - Including Sump

55 gal (US)

Note (1)

DEF Tank only available for EPA Tier 4 engine option.

Specification

Value

Struck

112.6-151 m³ (147-197.5 yd³)

Heaped (SAE 2:1)*

162-191 m³ (212-250 yd³)

Note (1)

Contact your local Cat dealer for body recommendation.

Note (2)

*ISO 6483:1980

Specification

Value

Steer Angle

36 °

Turning Diameter - Front

93.2 ft

Steering Standards

SAE J15111 OCT90, ISO 5010:1992

Specification

Value

ROPS Standards

ROPS (Rollover Protective Structure) for cab offered by Caterpillar meets ISO 3471:1994 ROPS criteria.

FOPS Standards

FOPS (Falling Objects Protective Structure) meets ISO 3449:1992 Level II FOPS criteria.

Specification

Value

Sound Standards

The operator sound pressure level measured according to work cycle procedures specified in ISO 6394 and 6396 is 76 dB(A) for cab offered by Caterpillar, when properly installed and maintained and tested with doors and windows closed.

Sound Standards (1)

Hearing protection may be needed when operating with an open operator station and cab (when not properly maintained or doors/windows open) for extended periods or in a noisy environment.

- The 793F is 6% faster than competitive trucks and delivers optimal speed on steep grades, poor underfoot conditions and haul roads with high rolling resistance.

- The C175-16 diesel engine’s 16-cylinder, four-stroke design uses long, effective power strokes for optimum efficiency. The 20% net torque rise provides unequaled lugging force during acceleration. Torque rise effectively matches transmission shift points for maximum efficiency and fast cycle times.

- An empty weight advantage of at least 9 tonnes (10 tons) over competitive electric-drive trucks in its size class ensures you’re getting the full payload you expect. And when you choose the High Performance (HP) body option, you’ll reduce weight an additional 2.0-5.0 tonnes (2.2-5.5 tons).

- The Cat six-speed transmission, with the latest APECS controls, is paired with the C175-16 engine to deliver optimum power over a wide range of operating speeds.

- The lock-up torque converter engages at approximately 8 km/h (5 mph), delivering unsurpassed stall torque for its size class. Cat final drives work as a system with the upper powertrain to deliver maximum power to the ground.

- Machine-level access and egress is enhanced with slip-resistant surfaces, guard rails, and a standard 600 mm (24 m) diagonal stairway across the front of the machine. An optional powered access stairway is available.

- Resiliently mounted to the main frame to reduce vibration and sound, the integral ROPS structure is an extension of the truck frame and exceeds SAE requirements.

- A lockout/tagout box mounted on the front bumper includes engine shutdown switch, battery lockout, starter lockout and transmission lockout.

- The standard Cat MineStar™ Detect Object Detection system combines radar and camera systems to warn operators about hazards within the immediate vicinity, while the optional Detect Driver Safety System alerts the operator if fatigue or distraction are detected.

- The 793F features four-corner oil-cooled brakes and Automatic Retarding Control to improve handling and machine control so operators can work quickly and confidently. With retarding power applied to all four corners, the full weight of the truck can be applied for traction, resulting in better control, more operator confidence and typically higher speeds in poor underfoot conditions.

- With multiple cab options, the 793F can be equipped with the desired features for your operation.

- All options offer an ergonomic layout, excellent all-around visibility, and controls, levers and switches that are positioned for ease of use.

- The cab includes dozens of features designed to enhance comfort, such as automatic climate control and sound suppression.

- The next generation seat includes a height adjuster; adjustable shoulder stock to keep seatbelt from rubbing on the operator’s neck; and seat back, side and lumbar bolsters to increase stability.

- Time spent on regular maintenance procedures is reduced thanks to features such as extended service intervals; grouped ground-level maintenance and checkpoints; easy access to major components; the standard AutoLube system; sealed electrical connectors; oil level sight gauges and front wheel sight glass; and service platforms on the engine and transmission.

- An optional 100% airless electric start option eliminates air system maintenance from the machine and improves uptime.

- The Cat Enhanced Engine Oil Filtration System increases engine life, eliminates cartridge filter changes and makes it possible to extend oil change intervals.

- The 793F can be equipped with an optional fast-fill service center with Live S•O•S℠ Service Center and brake wear indicators.

- New and updated machines have extended oil and filter change intervals across the majority of compartments.

- The 793F has been improved with longer-life components, extended service intervals and easier maintenance to deliver mechanical availability that is consistently greater than 90%.

- The 793F is built on our most durable 231-tonne (255-ton) frame ever built, backed by unprecedented levels of virtual and in-iron validation.

- A mild steel frame provides flexibility, durability and resistance to impact loads. Castings are used in high-stress areas and the integral 4-post ROPS cab provides increased strength.

- Component life is enhanced thanks to the standard rear-axle continuous filtration feature. Cleaner oil helps promote longer lubrication that leads to longer life.

- The frame, powertrain, engine and components are built to be rebuilt — delivering multiple lives of like-new performance at a fraction-of-new price.

- Cat bodies are the best choice for the 793F. They’re designed to be an integral part of the entire machine system, ensuring you achieve maximum chassis life.

- The High Performance (HP) body features a lightweight, simplified and durable design that provides complete front machine coverage and extended overhead protection.

- The X Body uses the Cat Mine Specific Design process to create a body that is properly sized and configured to meet the specific requirements of heavy-duty applications.

- Lightweight MSD II bodies are intended for established mines and are customized to suit your specific mining applications.

- The Gateless Coal Body is intended for dedicated coal haulage applications. It can be loaded to achieve target payload across the full range of coal densities.

- The 793F is designed to use less fuel, which reduces engine emissions, and there is zero fuel burn during retarding. The optional Tier 4 Final engine reduces NOx and particulate matter.

- Features like rear axle filtration, extended life filters and longer maintenance intervals decrease the amount of waste contributed to the environment.

- The Cat Common Rail Fuel System provides optimal fuel delivery, which reduces both fuel consumption and emissions output.

- The 793F engine is compatible with diesel fuel blended with lower-carbon intensity fuels such as biofuels and renewable fuels.

- By rebuilding machines and components, the Cat Rebuild and Cat Reman programs preserve raw materials, conserve energy and reduce emissions.

- MineStar Fleet is a fleet monitoring system that can be used to measure, manage and maximize the overall hauling operation.

- MineStar Command for hauling, an autonomous hauling solution proven to increase productivity up to 30%, is a fully integrated factory offering.

- Machine health solutions such as Equipment Care Advisor, Health Equipment Insights and Health Office enable a proactive approach to maintenance.

- The MineStar Detect Object Detection system comes standard on the 793F. Additional safety solutions include seat-belt monitoring and in-cab systems that intervene when they detect fatigue or distraction.