AP300

The AP300 is a small to mid-sized paver with a paving range from 1.75 m to 4.0 m (5.6 - 11.1 ft), making it a perfect fit for urban streets, cycle and walking paths, shoulders, as well as other small and medium job sites. A reduction option reduces the paving width to 700 mm (27 in) for trenches and other narrow applications. Technologically advanced features such as eco-mode, auto-fill, single-touch feeder activation, and automated travel mode make this paver and screed combination extremely productive and versatile for large and small contractors.

Standard Paving Range

1.75 - 3.42 m (5.6' - 11.1')

Engine Model (1)

Cat C3.3B

Engine Power (1)

73.8 HP

Specification

Value

Standard Paving Range

1.75 - 3.42 m (5.6' - 11.1')

Maximum Throughput Capacity

447 ton(US)/h

Maximum Travel Speed

10 mile/h

Maximum Paving Speed

200 ft/min

Maximum Paving Width

13.1 ft

Minimum Paving Width

27.5 in

Specification

Value

Engine Model (1)

Cat C3.3B

Engine Power (1)

73.8 HP

Specification

Value

Operating Weight - With SE34 VT

18078 lb

Operating Weight - With SE34 V

17637 lb

Shipping Weight - Paver Only

14550 lb

Specification

Value

Wheel Base

6.45 ft

Operating Length

16.5 ft

Operating Width

10.4 ft

Operating Height - With Canopy

11.2 ft

Transport Height

8.6 ft

Transport Width

6.3 ft

Transport Length

16.4 ft

Specification

Value

Fuel Tank

29 gal (US)

Cooling System (1)

2.4 gal (US)

Engine Oil (1)

3.5 gal (US)

Washdown Spray Tank

6.2 gal (US)

- Standard paving range of 1.75 m - 3.2 m (5' 9" - 11' 2") with a maximum width of 4 m (13' 1") deliver excellent performance for parking lots, urban streets, pathways, trenches, narrow shoulders, and other mid-sized applications

- An optional paving reduction attachment narrows the paving width to 700 mm (27.5")

- Heated end gates, variable frequency vibration, and tamper bar settings help provide smooth material flow

- Exclusive Eco-mode and automatic engine speed control, reduce fuel consumption and lower sound levels for better comfort and communication

- Auto-fill feeder system simplifies setup by filling the auger chamber to the set point determined by the feed sensors

- Single touch feeder system activation optimizes efficiency by activating each auger and each conveyor

- Automated travel feature; augers raise with the screed, preventing damage during transport

- Single-touch hopper control enables operators to concentrate on other duties

- Engine options available to meet U.S. EPA Tier 4 Final, EU Stage V emissions and other regional standards

- Million cycle switches provide reliability

- Conveyor bed plates and chain guards designed to minimize labor requirements and provide lower cost replacement

- Heating elements slide out for easy replacement

- Machined screed frames simplify screed plate leveling

- Strategically located dealers with 24/7 support

- In-the-Iron service training for technicians

- Paver Operator Training helps maximize machine performance

- Project consulting helps improve technique and job site management

- Ventilation system option draws fumes from the auger chamber and redirects them away from the operator for a more comfortable working environment

- Single sliding console enables operation from either side of the machine

- Dual independent seats swing out beyond the platform for good visibility to curbs and obstacles

- Heated seat option delivers comfort in cool weather conditions

- High visibility 76 mm (3") seat belt helps with crew safety compliance

- Operating displays can be tailored to specific language requirements with multiple options available

- Easy access to generator activation, screed temperature control, screed heating zones, tamper and vibratory speeds, and service code information

- Intuitive symbols and large graphics simplify operation

- Adjustable brightness control for easy viewing day or night

- Raised switch design enables easy recognition for better efficiency and performance

- SE34 V and SE34 VT screeds deliver excellent ride, density, and mat texture while providing superior adjustment capabilities

- Basic Grade Control option available

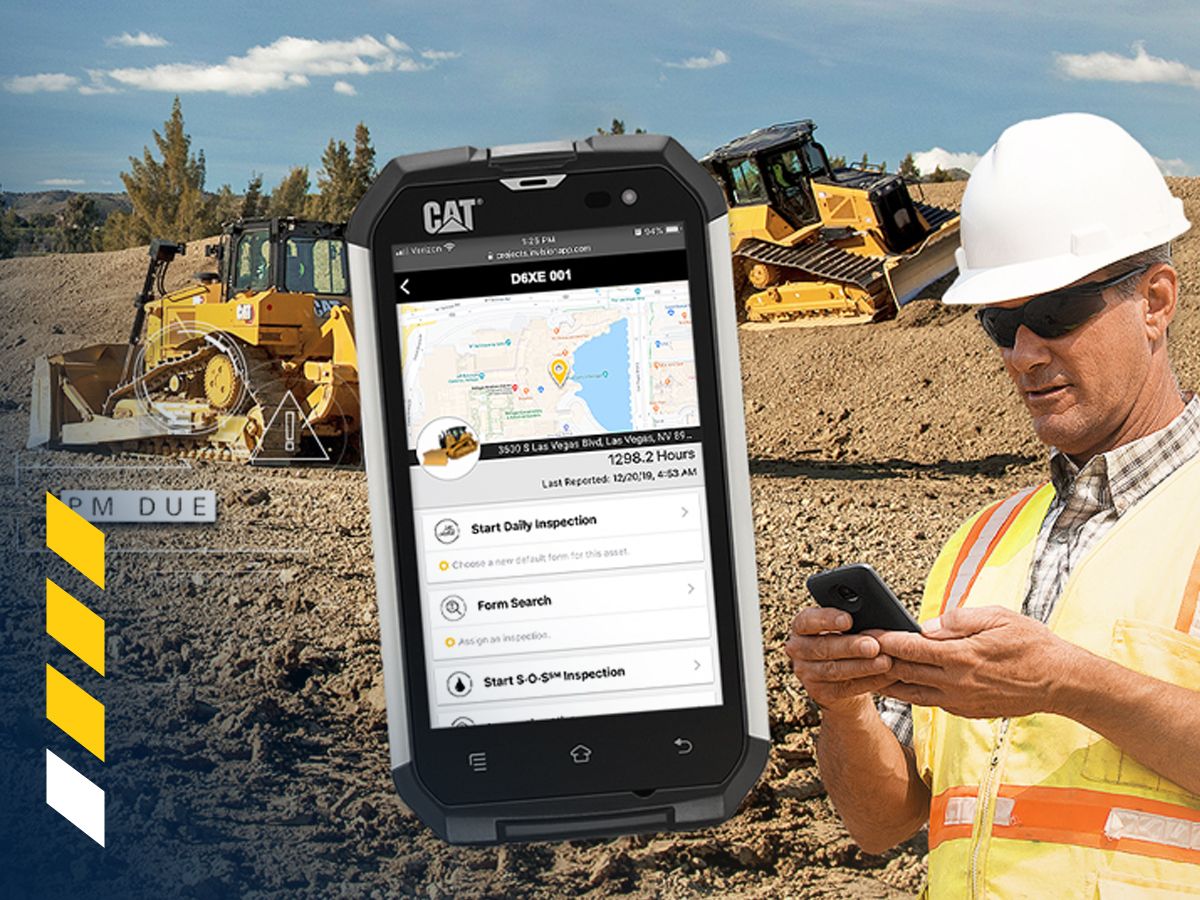

- Make timely, fact-based decisions to maximize efficiency, improve productivity, and lower owning and operating costs

- Easily track location, machine hours, fuel usage, and idle time in real time

- Diagnostic codes are made available through online web applications

- Scheduled maintenance and Scheduled Oil Sampling notification

- Paver and screed service and repair kits include all the parts necessary to complete specific repairs

- Cat genuine parts are manufactured to precise specifications and designed for optimal performane and maximum uptime

- Repair kits are identified by a single part number to make ordering easy

- Select kits are available to be packaged as a kit by the dealer for over-the-counter purchases or through the dealer service shop