Cat Grade with Grade and Slope for Cold Planers

Cat® GRADE with Grade and Slope for cold planers allows milling operators to achieve accurate and repeatable cutting results to provide a smooth base for any project. The integrated system uses automated features to take the guesswork out of producing a consistent cut every time.

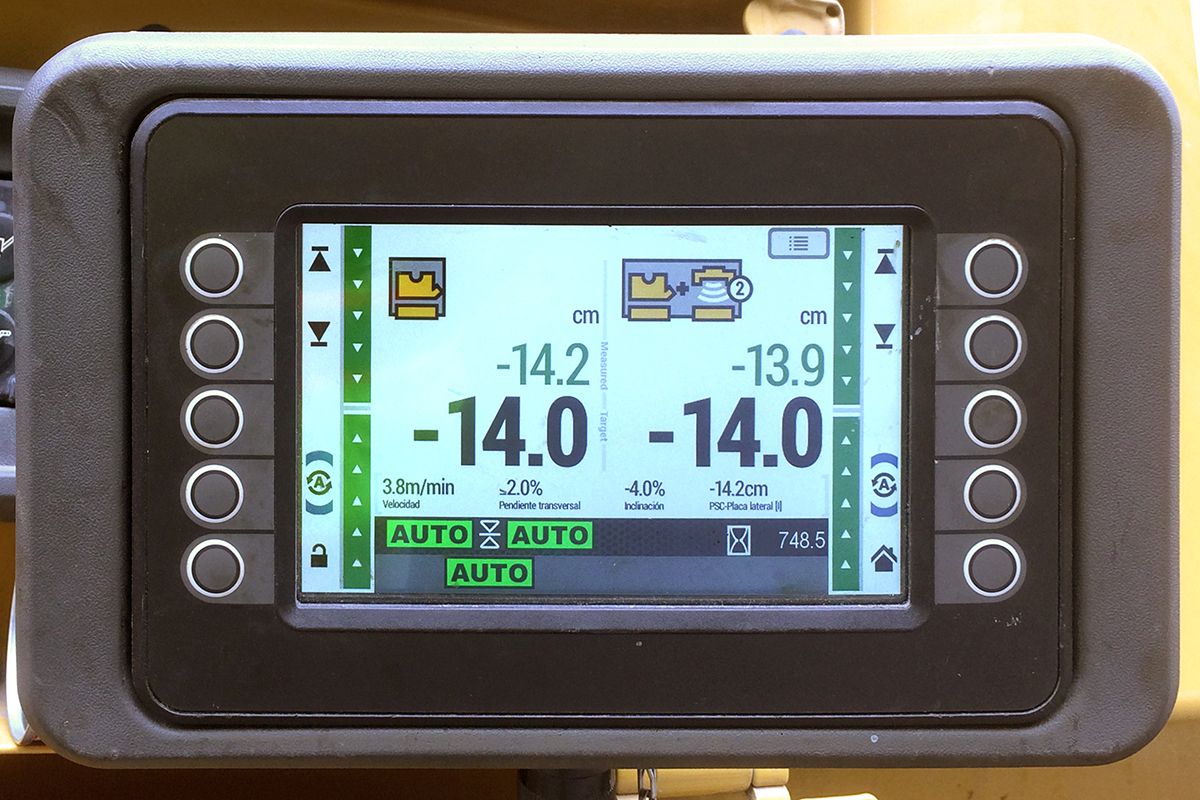

- The easy-to-use interface and system design is similar to the Cat GRADE system used on Cat pavers and is nearly identical on all Cat cold planers, offering enhanced functionality on certain models.

- Operators can gain full control over grade and slope from any of the control boxes located on the operator platform or at ground level.

- Grade and Slope enhances other features on the machine such as automated transitions into or out of a cut, adjustable plunge velocity, obstacle jump and the Standby and Resume function.

- Easily set and execute grade and slope transitions for tapered start or end cuts over a specified distance.

- Adjust the speed at which the rotor drops into the cut for optimal machine control.

- Clear obstacles in the cutting path with ease using the obstacle jump feature.

- Seamlessly swap between multiple grade sensors for uninterrupted accuracy during milling.

- Control boxes can be repositioned without the need to reconfigure settings.

- Contacting (side plate or inboard ski) and non-contacting (sonic) sensors provide multiple grade references.

- Specific jobsite settings can be saved and recalled on future jobs for reduced setup time and consistent results.

- Enhance with 3D milling using a similar system and components to other Cat products, built off of the integrated 2D grade and slope system (additional hardware required).

- Built-in diagnostics monitor machine systems, alert the operator of performance issues and provide troubleshooting information.

- Service for the Cat GRADE system is provided by your Cat dealer, offering convenient parts availability and remote troubleshooting capability.