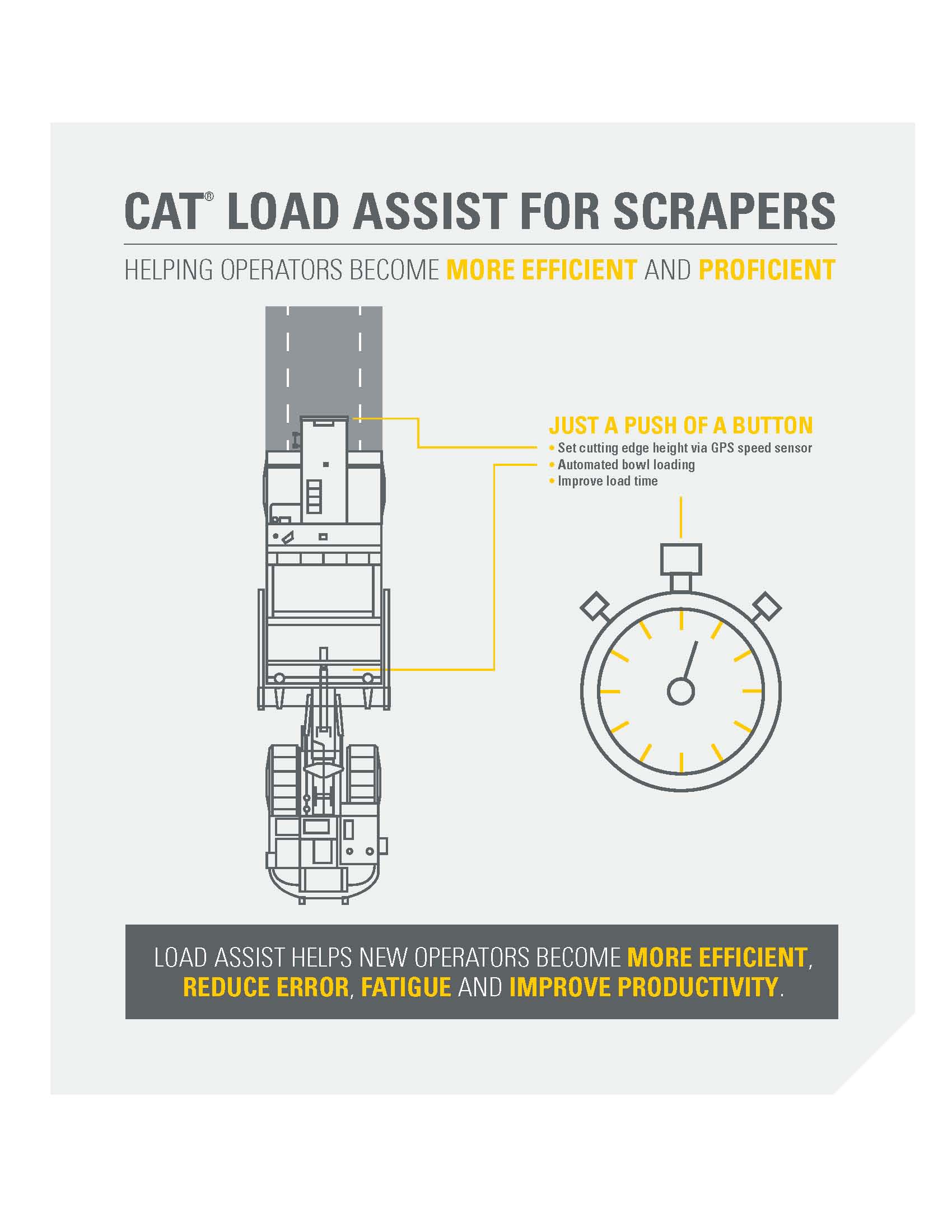

- Load Assist automates inputs to help inexperienced operators maintain efficiency and shorten the learning curve.

- Functions for Push-Pull, Push-Loading and Self-Loading applications are simplified for new operators using Load Assist.

- Load Assist uses a GPS speed sensor and additional machine information to control cutting edge depth during the loading sequence.

- Work confidently without guesswork by integrating Load Assist, Sequence Assist, and Cat Grade Control.

- Machine components are built in at the factory for better performance, security, and support.

- Load Assist helps less experienced operators become proficient and get to design plan faster.

- Control buttons are integrated into the implement control joystick for easy operation.

- Bowl loading is automated with the push of a button, helping to reduce operator fatigue.

- Load Assist works in conjunction with external site system solutions for boosted productivity.

- Load Assist helps inexperienced operators maximize the cutting depth and automate bowl control during the loading cycle.

- As the machine approaches the cut, the operator activates Load Assist with the push of a button to automate the cutting-edge height.

- Increase efficiency and productivity through a reduction in time, fuel, and passes.

- Automated controls help operators minimize tire slip and fuel burn.

- Load Assist is ordered with the machine and supported by your Cat dealer or SITECH® technology partner.

Load Assist is not available for 637 Coal Bowl and 657 Coal Bowl machines.