Specification

Value

Net Power - ISO 9249

113 HP

Engine Model

C4.4

Engine Power - ISO 14396

125 HP

Bore

4.13 in

Stroke

5 in

Displacement

269 in³

Specification

Value

Main System - Maximum Flow

272 l/min (72 gal/min)

Maximum Pressure - Equipment

5080 psi

Maximum Pressure - Swing

3280 psi

Specification

Value

Swing Speed

8.9 r/min

Maximum Swing Torque

32970 ft·lbf

Specification

Value

Operating Weight

39463 lb

Specification

Value

Fuel Tank Capacity

79.3 gal (US)

Cooling System

5.2 gal (US)

Engine Oil

4.3 gal (US)

Swing Drive

0.8 gal (US)

Final Drive - Each

1.6 gal (US)

Hydraulic System - Including Tank

26 gal (US)

Hydraulic Tank

22 gal (US)

Specification

Value

Boom

Reach 5.1 m (16'9")

Stick

R2.6 m (8'6")

Bucket

GD .76 m³ (1.0 yd³)

Shipping Height - Top of Cab

9.92 ft

Shipping Length

28 ft

Tail Swing Radius

8.17 ft

Counterweight Clearance

3.25 ft

Ground Clearance

1.5 ft

Track Length

13 ft

Length to Center of Rollers

10.42 ft

Track Gauge

6.5 ft

Transport Width

8.5 ft

Specification

Value

Maximum Digging Depth

20 ft

Boom

Reach 5.1 m (16'9")

Stick

R2.6 m (8'6")

Bucket

GD .76 m³ (1.0 yd³)

Maximum Reach at Ground Level

28.8 ft

Maximum Cutting Height

29.3 ft

Maximum Loading Height

20.6 ft

Minimum Loading Height

7.6 ft

Maximum Depth Cut for 2440 mm (8 ft) Level Bottom

19.3 ft

Maximum Vertical Wall Digging Depth

16.3 ft

Bucket Digging Force - ISO

25000 lbf

Stick Digging Force - ISO

17900 lbf

- A powerful C4.4 electrically controlled engine meets U.S. EPA Tier 3, EU Stage IIIA equivalent and China Nonroad Stage III emission standards.

- Two-pump hydraulic system pressure delivers terrific digging performance and productivity.

- Hydraulic cross-sensing system uses two hydraulic pumps under all operating conditions, improving productivity with faster implement speeds and quicker, stronger pivot turns.

- Economy mode maintains breakout forces and lift capacity at standard power, balancing demands of performance and fuel economy.

- Boom and stick regeneration circuits save energy during boom-down and stick-in operation.

- New compact design utilizes shorter tubes and lines to reduce friction and pressure drops, resulting in more efficient use of power.

- The service door on the right side of the upper structure allows ground-level access to the pump, pilot filter, drain filter, and the engine oil filter.

- Easily accessible, ground-level service locations allow quick and efficient maintenance.

- The left service door allows easy access to the engine radiator, oil cooler, air-to-air-aftercooler, primary filter with water separator (if the two are integrated) and secondary fuel filter.

- The radiator air filter features a double-element construction for superior cleaning efficiency; a warning is displayed on the monitor screen inside the cab when the filter plugs.

- An adjustable seat and joystick console are designed to meet individual preferences.

- Low-effort pilot-operated joystick controls are designed to match natural wrist and arm position for maximum comfort and minimum fatigue.

- The full-color LCD monitor is programmable in 42 languages.

- The cab shell is attached to frame with viscous rubber mounts to dampen vibrations and sound levels, enhancing operator comfort.

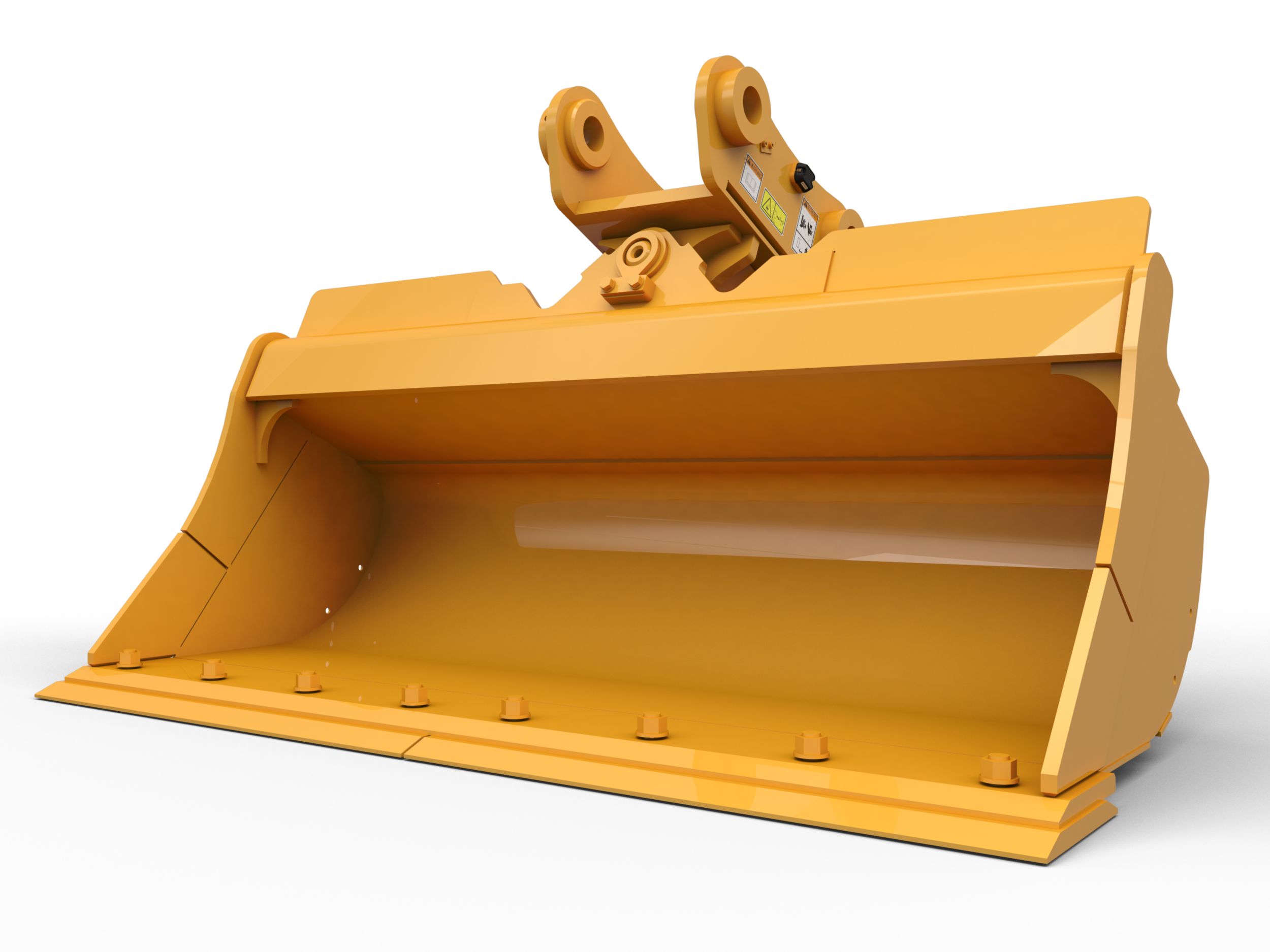

- Site prep and finishing work are quick and easy with a Cat® grapple, thumb, and hammer.

- Utility work is fast and flawless with a Cat bucket and compactor.

- A coupler lets you swap between attachments in seconds without leaving the cab.

- See the whole money-making attachment line for your machine at www.cat.com/attachments.

- The modified X‐frame structure provides a long service life.

- Robot-welded and stress-relieved heavy duty boom and stick are standard.

- Track shoes, links, rollers, idlers, and final drives are built with high‑tensile-strength steel.

- Greased track link between pins and bushings increases undercarriage life and reduces noise.

- Anti-skid plating covering the entire upper structure and storage box prevents slipping during maintenance.

- Countersunk bolts reduce trip hazards during service and maintenance.

- The engine radiator fan is enclosed by fine wire mesh, reducing risk of an accident.

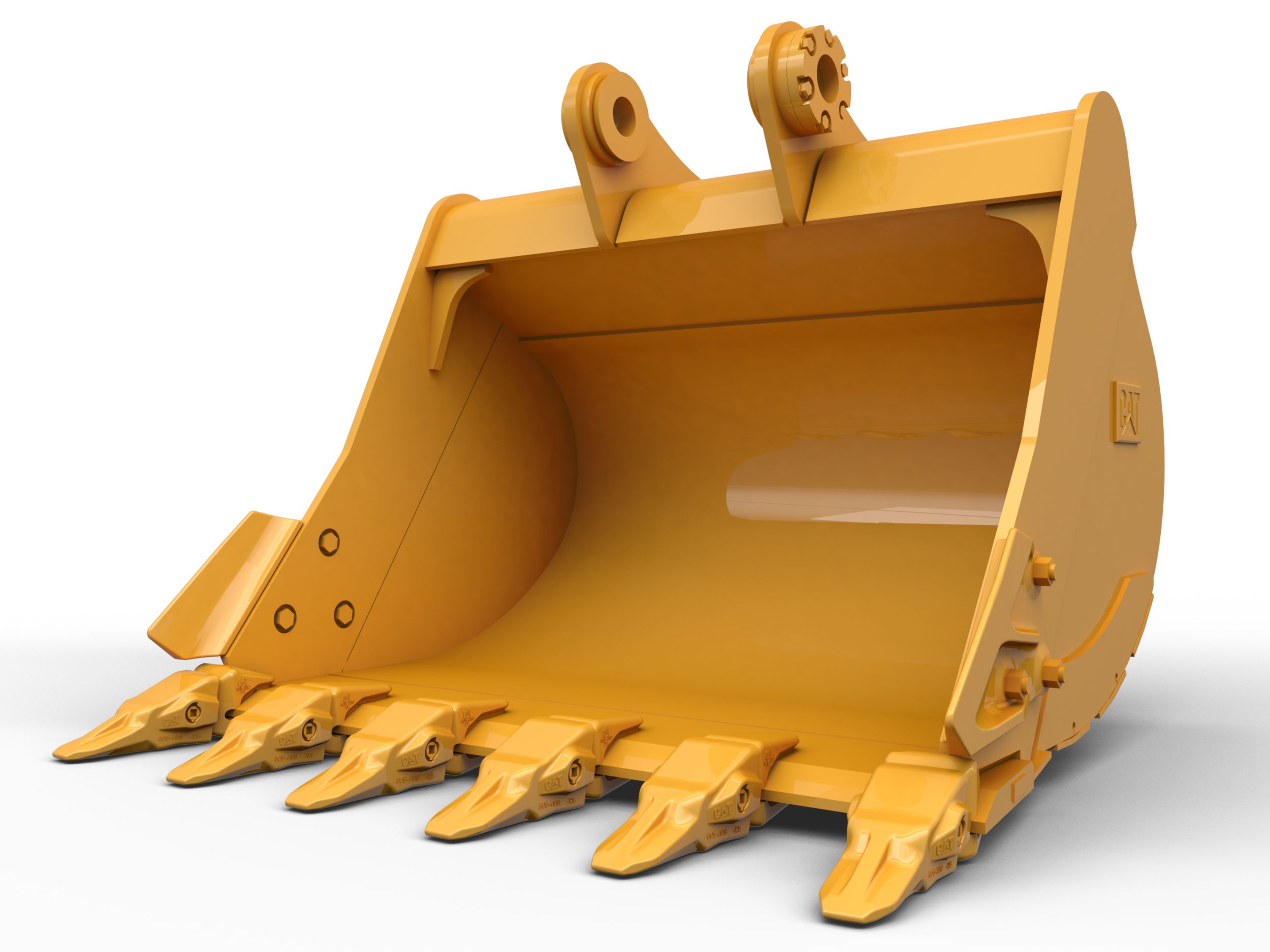

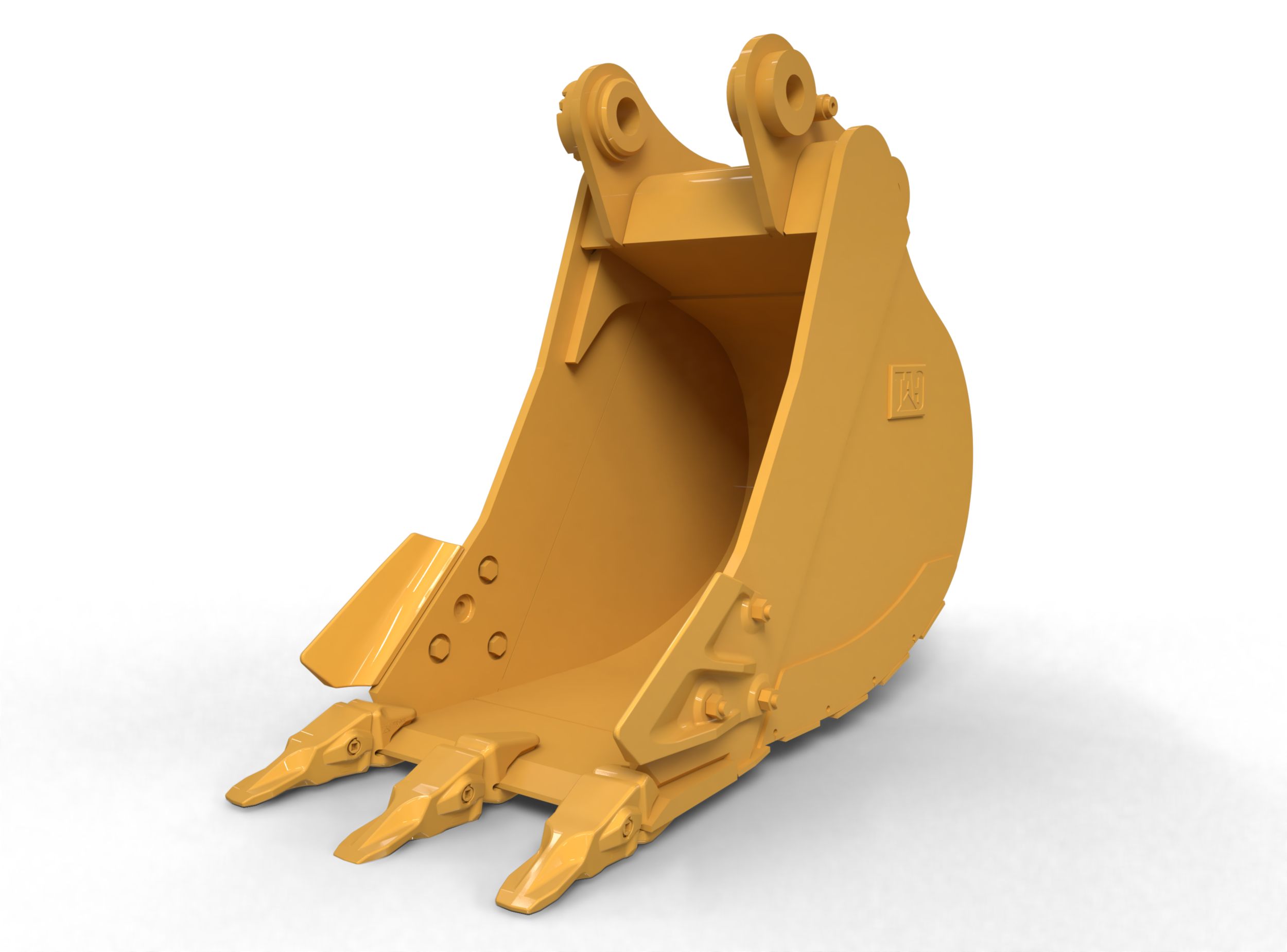

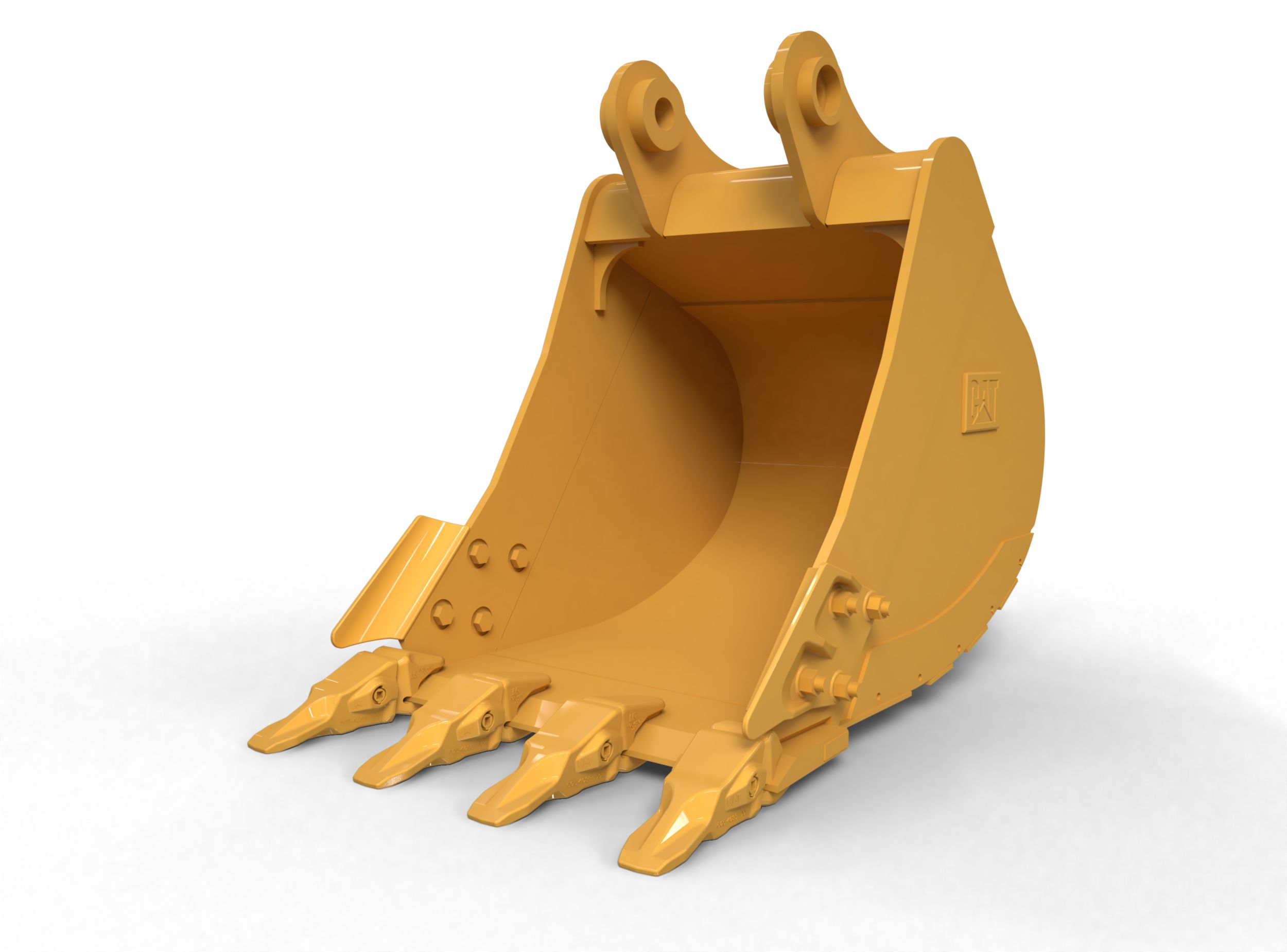

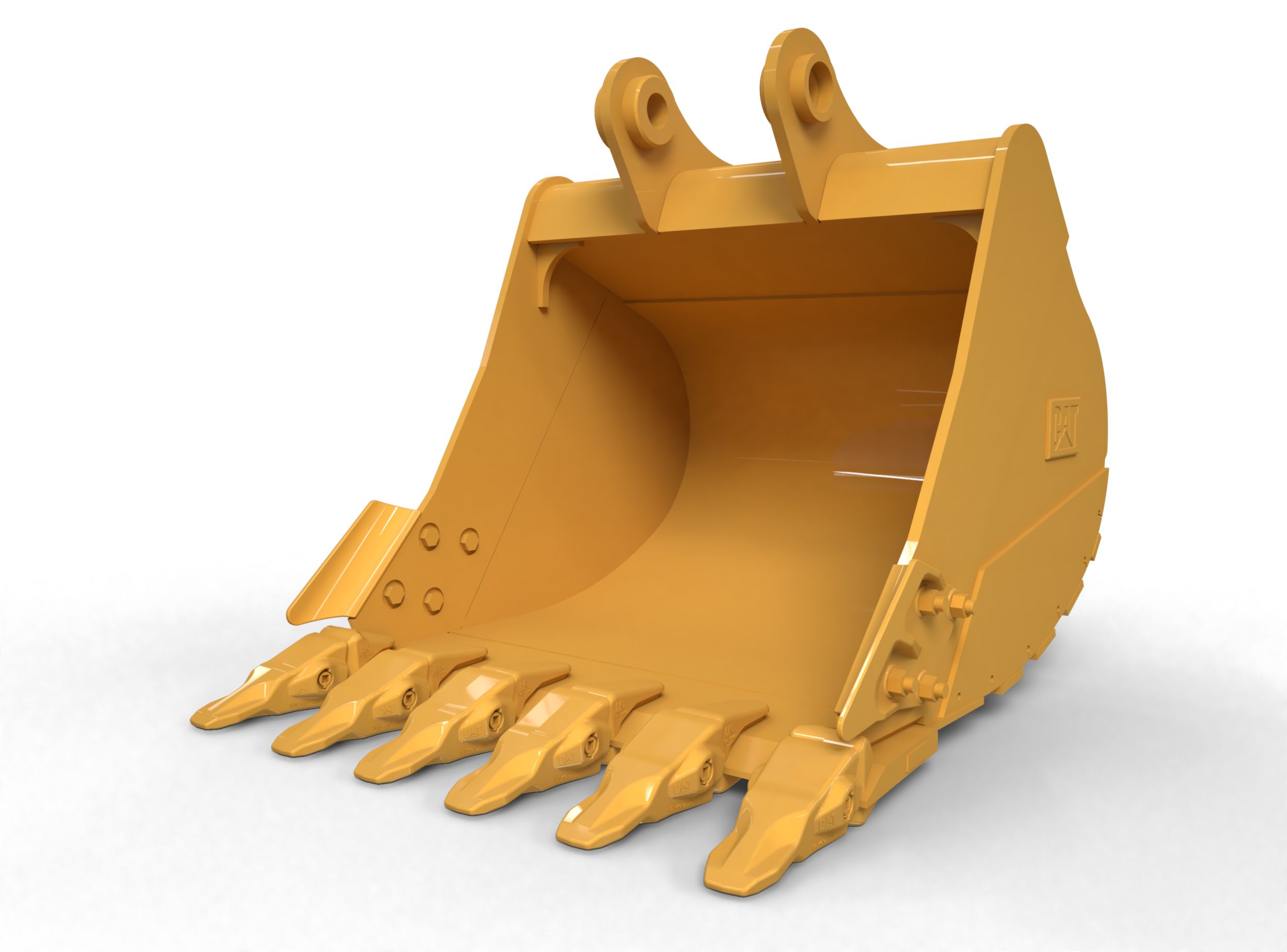

General Duty Bucket 1400 mm (55 in): 554-3127

General Duty - Leveling Edge Bucket 1400 mm (55 in): 471-0120

General Duty - Leveling Edge Bucket 650 mm (25 in): 488-8415

General Duty - Leveling Edge Bucket 750 mm (29 in): 477-3375

General Duty - Leveling Edge Bucket 950 mm (37 in): 477-3376

General Duty - Leveling Edge Bucket 1150 mm (45 in): 477-3377

General Duty - Leveling Edge Bucket 1350 mm (53 in): 479-8870

General Duty - Leveling Edge Bucket 600 mm (24 in): 490-4017

General Duty - Leveling Edge Bucket 800 mm (31 in): 490-4018

General Duty - Leveling Edge Bucket 1000 mm (39 in): 490-4019

General Duty - Leveling Edge Bucket 1200 mm (47 in): 490-4020

General Duty - Leveling Edge Bucket 1400 mm (55 in): 490-4021

General Duty Bucket 1050 mm (42 in): 552-8151

General Duty Bucket 600 mm (24 in): 550-9344

General Duty Bucket 1200 mm (48 in): 552-8152

General Duty Bucket 750 mm (30 in): 550-9345

General Duty Bucket 600 mm (24 in): 550-9376

General Duty Bucket 1300 mm (51 in): 550-9349

General Duty Bucket 1200 mm (48 in): 550-9348

General Duty Bucket 900 mm (36 in): 550-9346

General Duty Bucket 1100 mm (43 in): 550-9347

General Duty Bucket 900 mm (36 in): 550-9378

General Duty Bucket 1200 mm (48 in): 550-9380

General Duty Bucket 1100 mm (43 in): 550-9379

General Duty Bucket 750 mm (30 in): 550-9377

General Duty Bucket 1400 mm (55 in): 550-9382

General Duty Bucket 1300 mm (51 in): 550-9265

General Duty Bucket 1200 mm (48 in): 550-9296

General Duty Bucket 600 mm (24 in): 550-9294

General Duty Bucket 900 mm (36 in): 550-9295

General Duty - Leveling Edge Bucket 996 mm (39 in): 455-0748

General Duty - Leveling Edge Bucket 1200 mm (47 in): 441-4768

General Duty - Leveling Edge Bucket 800 mm (31 in): 462-8167

General Duty Bucket 1300 mm (51 in): 550-9422

General Duty Bucket 600 mm (24 in): 550-9374

General Duty - Leveling Edge Bucket 650 mm (25 in): 481-1106

General Duty Bucket 750 mm (30 in): 550-9341

General Duty Bucket 1200 mm (48 in): 550-9342

General Duty Bucket 1300 mm (51 in): 550-9375

General Duty Bucket 1300 mm (51 in): 550-9343

Heavy Duty Bucket 1200 mm (48 in): 573-5012

Heavy Duty Bucket 1200 mm (48 in): 550-9417

Heavy Duty Bucket 1300 mm (51 in): 550-9418

Heavy Duty Bucket 1300 mm (51 in): 550-9371

Severe Duty Bucket 1050 mm (42 in): 552-8173

Severe Duty Bucket 1200 mm (48 in): 552-8174

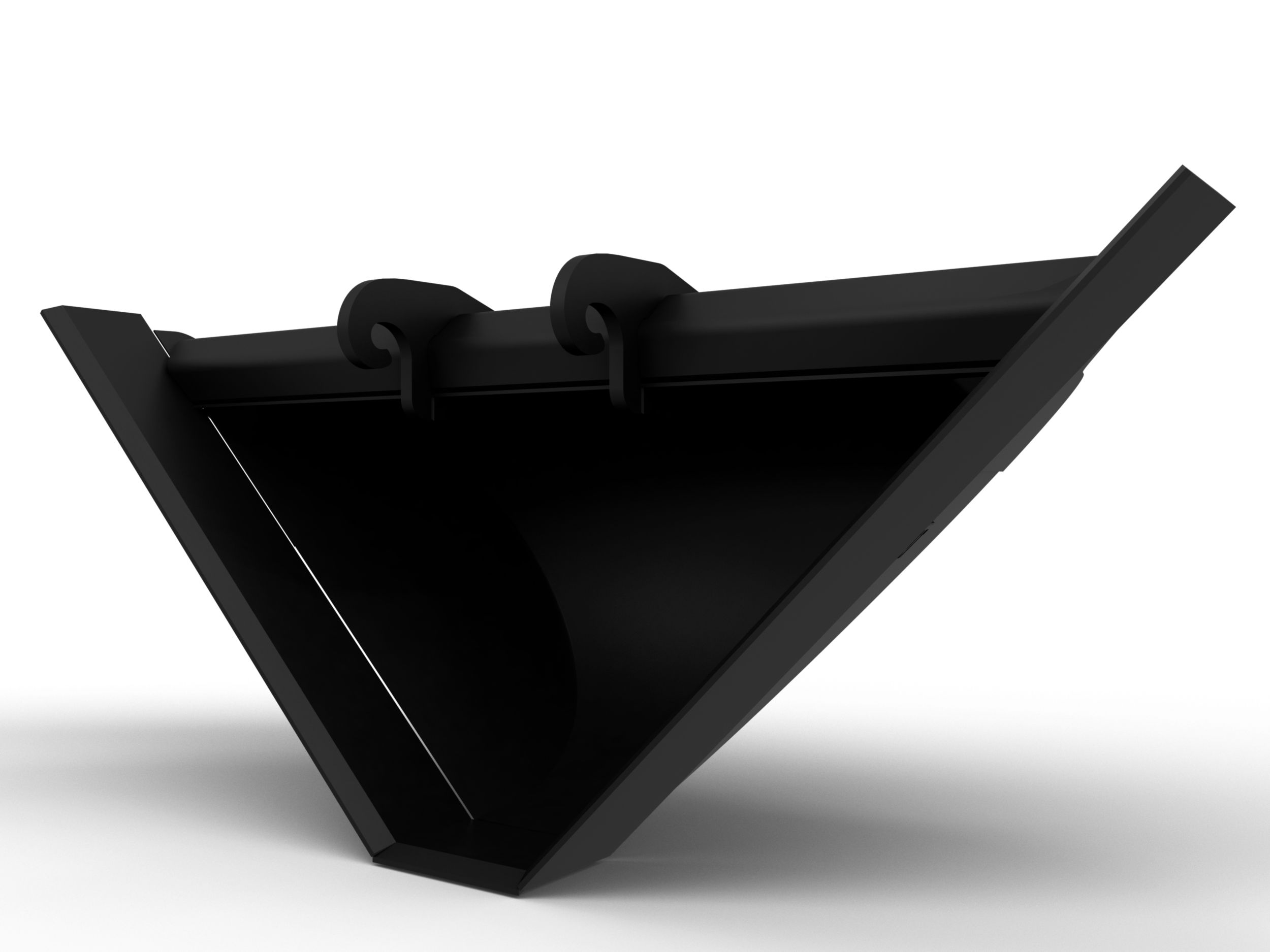

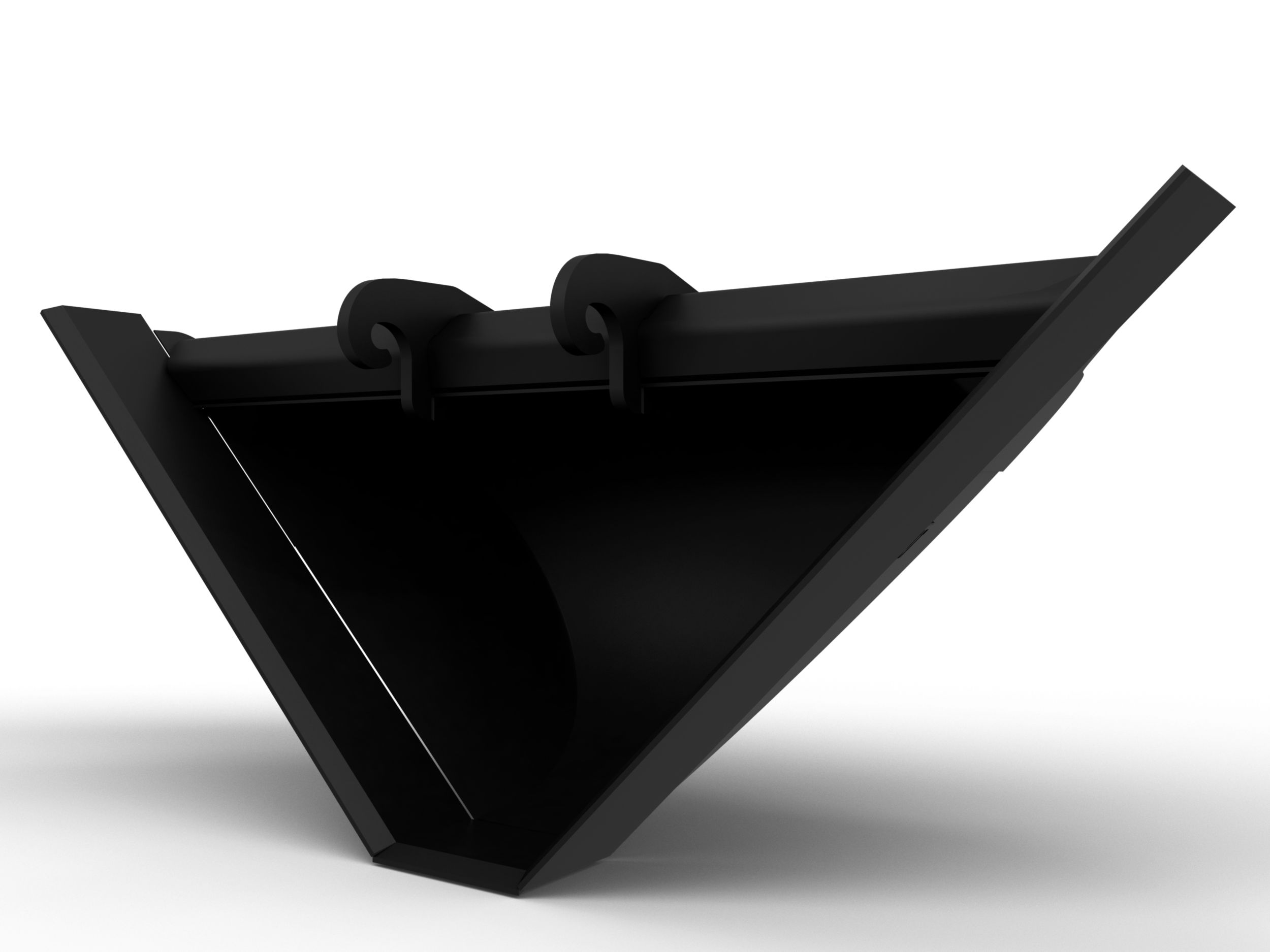

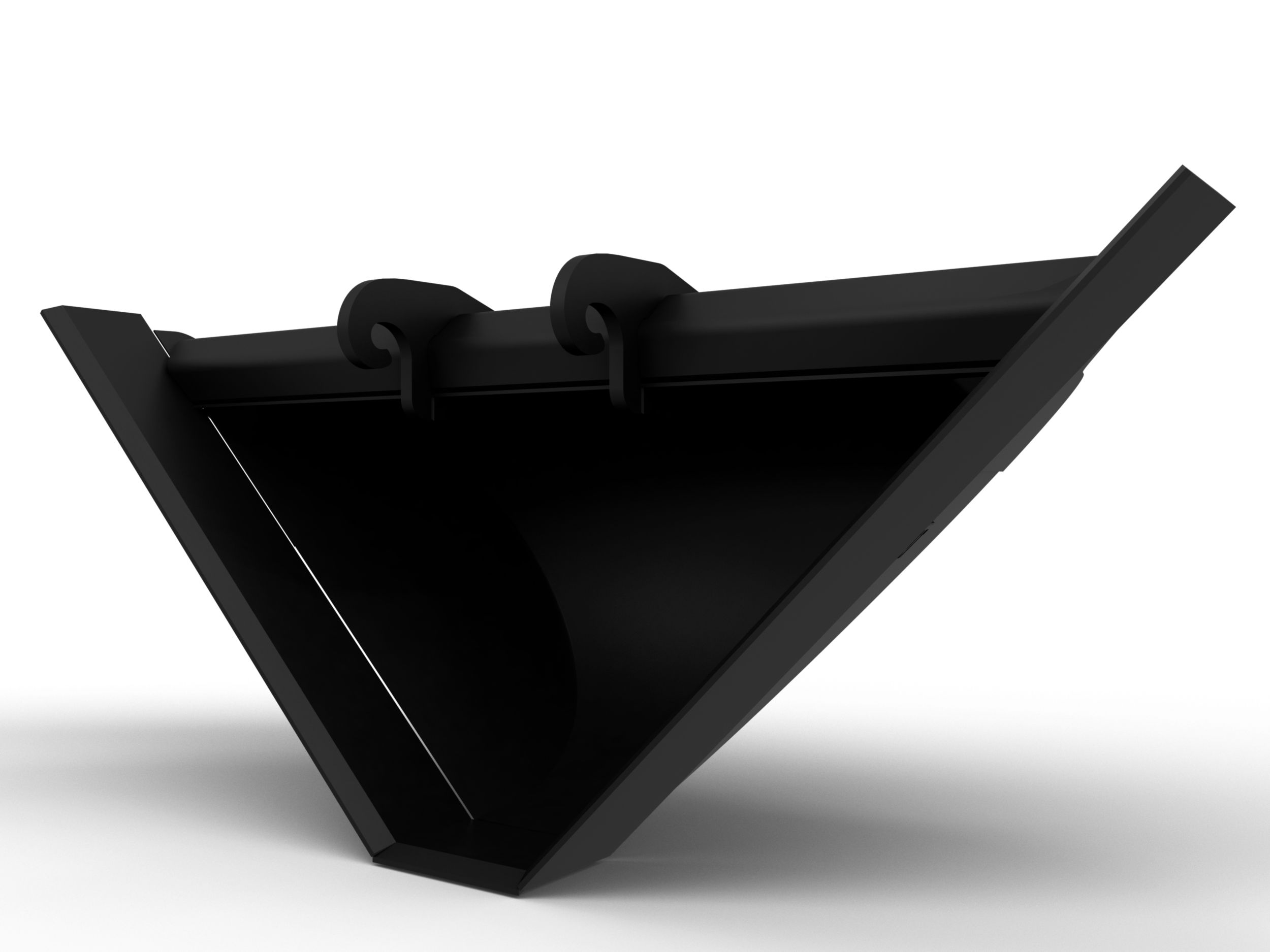

Ditch Cleaning Bucket 1800 mm (72 in): 439-7347

Ditch Cleaning Bucket 2100 mm (82 in): 439-7348

Ditch Cleaning Bucket 1800 mm (72 in): 439-7356

Ditch Cleaning Bucket 2000 mm (78 in): 442-8270

Ditch Cleaning Bucket 2000 mm (78 in): 442-8267

Ditch Cleaning Bucket 2000 mm (78 in): 442-8266

Skeleton - Light Duty Bucket 1300 mm (51 in): 187-8849

Skeleton - Light Duty Bucket 1300 mm (51 in): 187-8850

Skeleton - Light Duty Bucket 1300 mm (51 in): 187-8851

Skeleton - General Duty Bucket 1300 mm (51 in): 445-9117

Skeleton - Heavy Duty Bucket 1200 mm (47 in): 445-9116

Grading Bucket 1600 mm (63 in): 512-8401

Grading Bucket 1700 mm (66 in): 512-8413

Grading Bucket 1700 mm (66 in): 512-8414

Grading Bucket 1800 mm (70 in): 512-8400

Profile Bucket 300 mm (12 in): 287-5360

Profile Bucket 400 mm (16 in): 287-5361

Profile Bucket 500 mm (20 in): 287-5362

Trenching Bucket 660 mm (26 in): 512-8399

Utility Duty Bucket 650 mm (26 in): 187-7678

Utility Duty Bucket 650 mm (26 in): 221-0997

Utility Duty Bucket 750 mm (30 in): 186-6731

Utility Duty Bucket 1000 mm (39 in): 186-6726

Utility Duty Bucket 1100 mm (43 in): 221-9516

Utility Duty Bucket 1200 mm (48 in): 226-2144

Utility Duty Bucket 1200 mm (48 in): 226-2145

Ditch Cleaning Tilt Bucket 2000 mm (79 in): 510-6690

Ditch Cleaning Tilt Bucket 1800 mm (72 in): 510-6691

Ditch Cleaning Tilt Bucket 2000 mm (79 in): 510-6692

Ditch Cleaning Tilt Bucket 1800 mm (72 in): 510-6693

Ditch Cleaning Tilt Bucket 2000 mm (79 in): 510-6694

G318 Demolition & Sorting Grapple: 587-8965

G318 WH Demolition & Sorting Grapple: 587-8970

G318 Demolition & Sorting Grapple: 587-8966

G318 WH Demolition & Sorting Grapple: 587-8975

GSH420 4-Tine, 500-Liter Orange Peel Grapple

GSH420 4-Tine, 600-Liter Orange Peel Grapple

GSH420 4-Tine, 750-Liter Orange Peel Grapple

GSH520 5-Tine, 500-Liter Orange Peel Grapple

GSH520 5-Tine, 600-Liter Orange Peel Grapple

GSV520 GC 5-Tine, 400-Liter Orange Peel Grapple

GSV520 GC 5-Tine, 500-Liter Orange Peel Grapple

GSV520 GC 5-Tine, 600-Liter Orange Peel Grapple

GSV520 GC 5-Tine, 750-Liter Orange Peel Grapple

GSV520 5-Tine, 400-Liter Orange Peel Grapple

GSV520 5-Tine, 500-Liter Orange Peel Grapple

GSV520 5-Tine, 600-Liter Orange Peel Grapple

H115 S

H120 S

H130 S

MP318 Universal Jaw

MP318 Pulverizer Jaw

MP318 Shear Jaw

Cat® Detect with Smart Camera

Cat® Detect with Surround Cameras

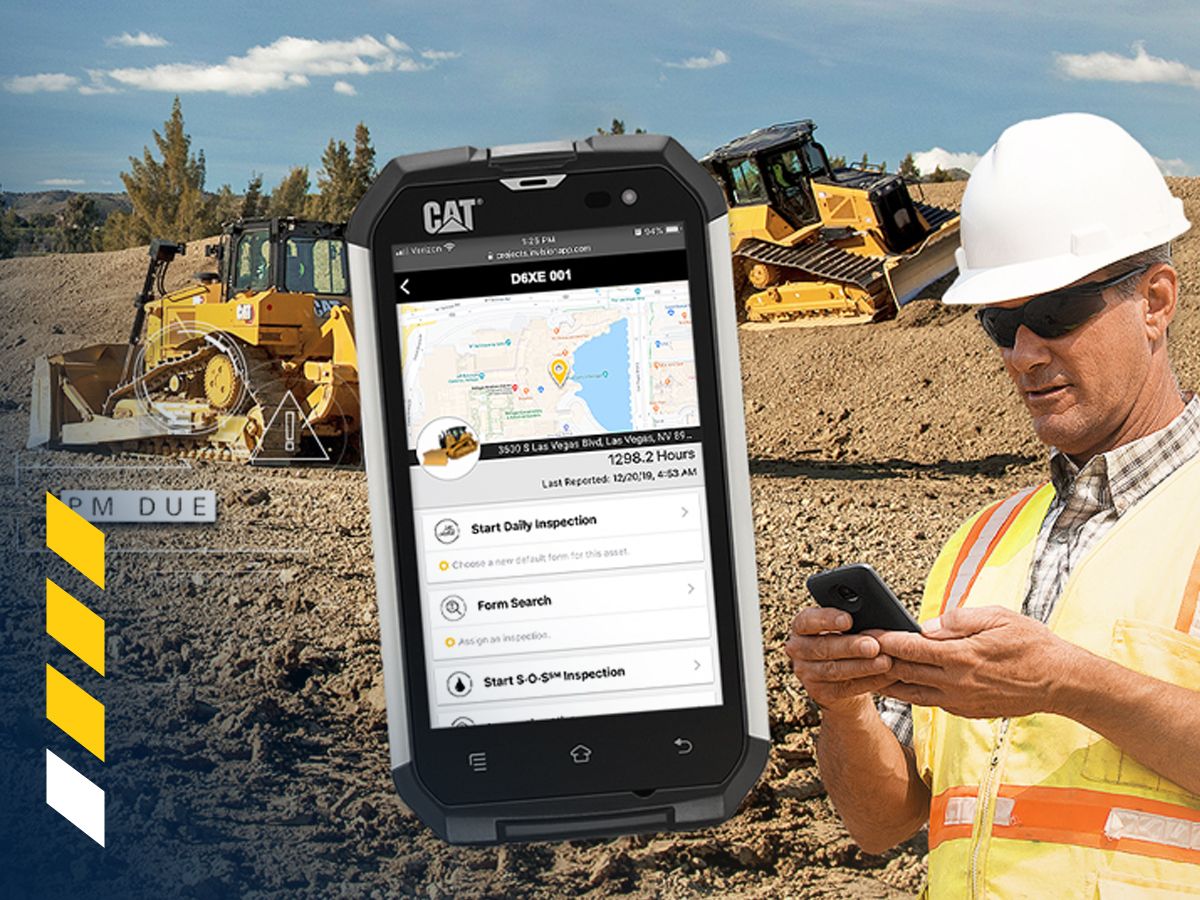

Cat Product Link

Cat Inspect

VisionLink®

Cat Grade with 3D for Excavators

Cat Grade Assist for Excavators

VisionLink® Productivity

G318 Demolition & Sorting Grapple: 595-1393

G317 GC Demolition & Sorting Grapple: 587-8720

G317 GC Demolition & Sorting Grapple: 587-8721

MP318 Demolition Jaw

MP318 Concrete Cutter Jaw

Cat Grade with 2D for Excavators

Cat Payload for Excavators