RM400

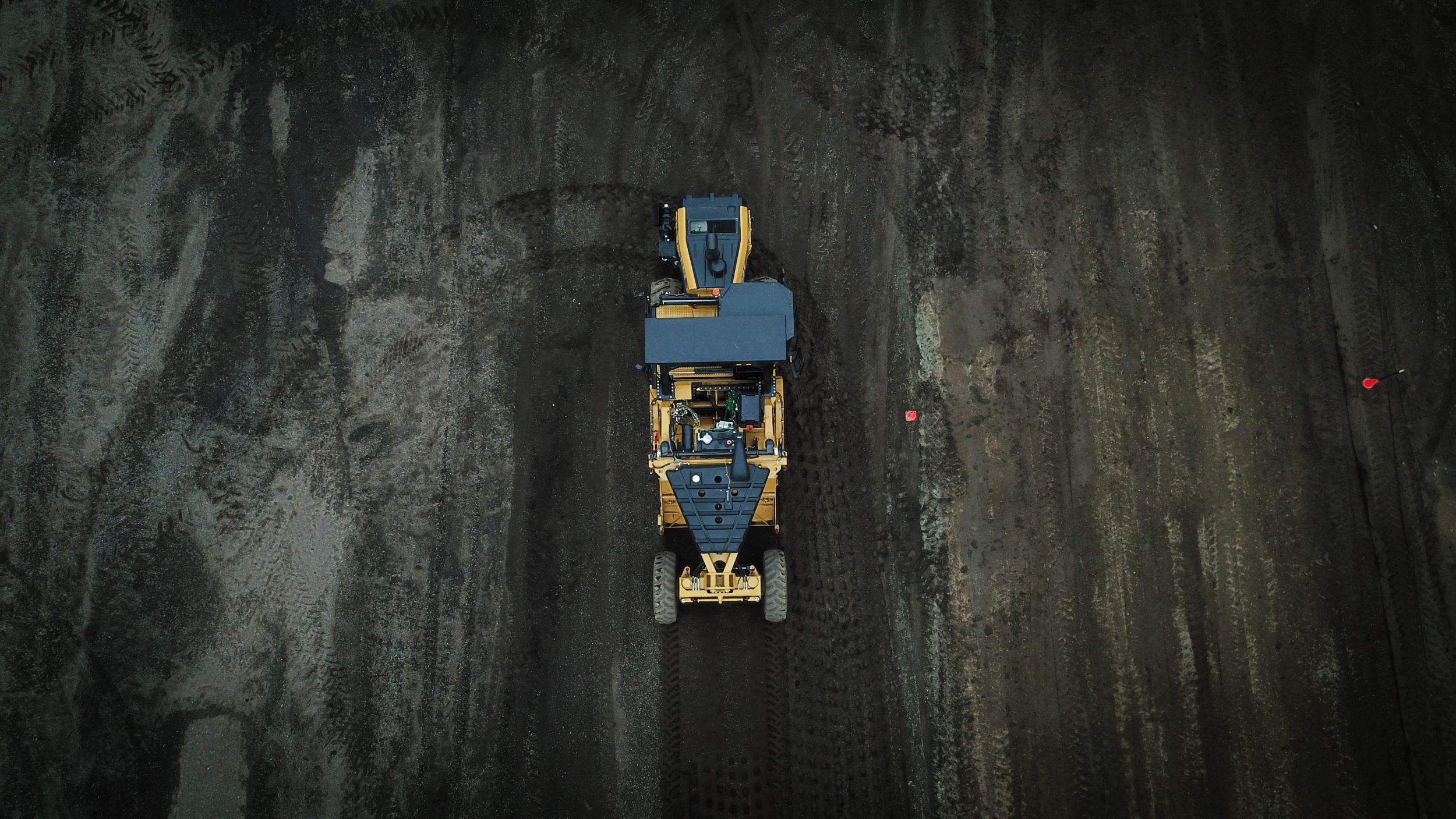

The versatile Cat® RM400 Reclaimer/Stabilizer delivers excellent material gradation, outstanding maneuverability, and simple operation with superb visibility for excellent overall job site performance. Your toughest road rehabilitation and soil stabilization jobs have met their match.

Maximum Operating Weight

57232 lb

Cutting/Mixing Width

96 in

Maximum Cutting/Mixing Depth

20 in

Specification

Value

Maximum Operating Weight

57232 lb

Specification

Value

Cutting/Mixing Width

96 in

Maximum Cutting/Mixing Depth

20 in

Operating Speed

2.97 mile/h

Maximum Travel Speed

6.8 mile/h

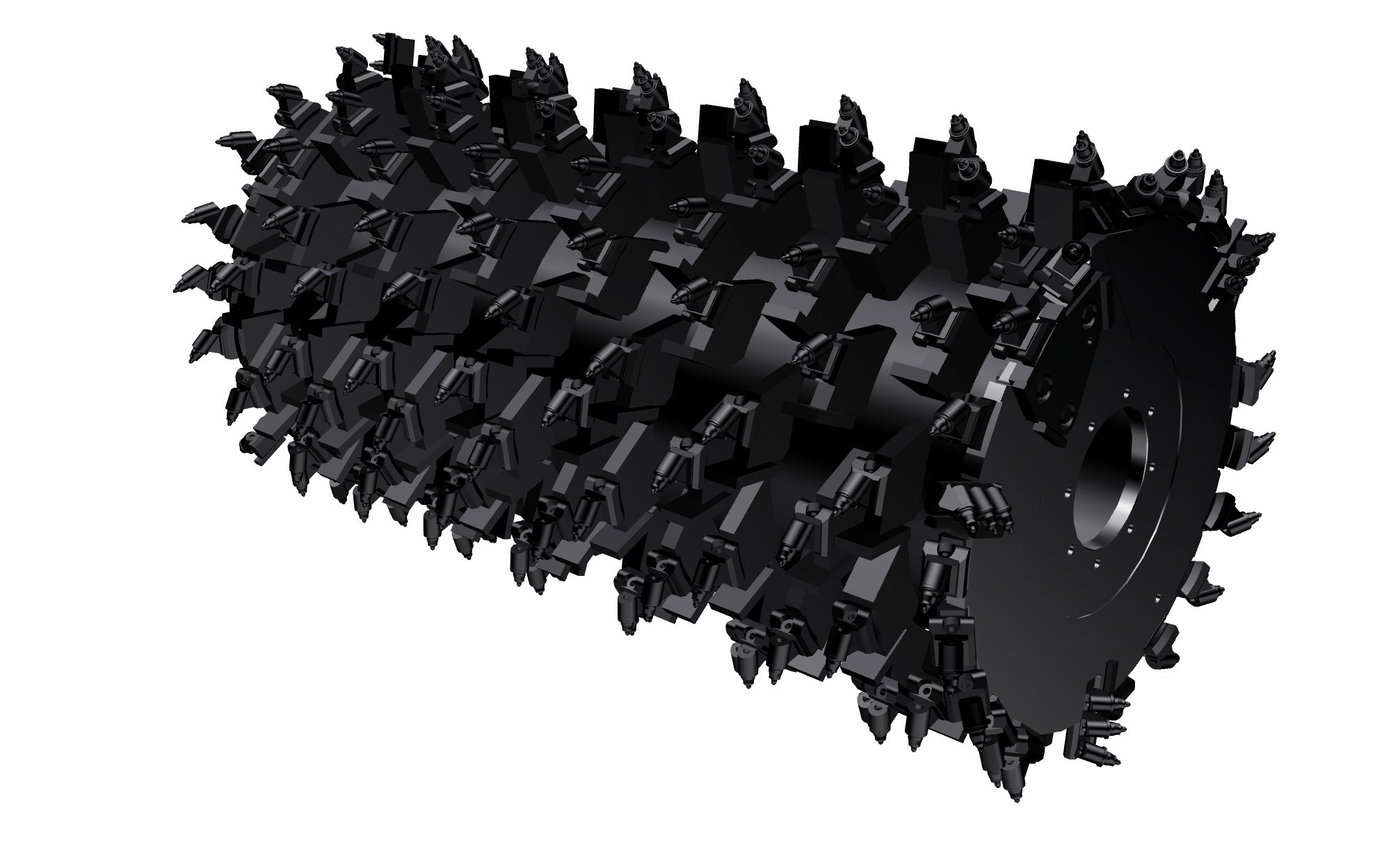

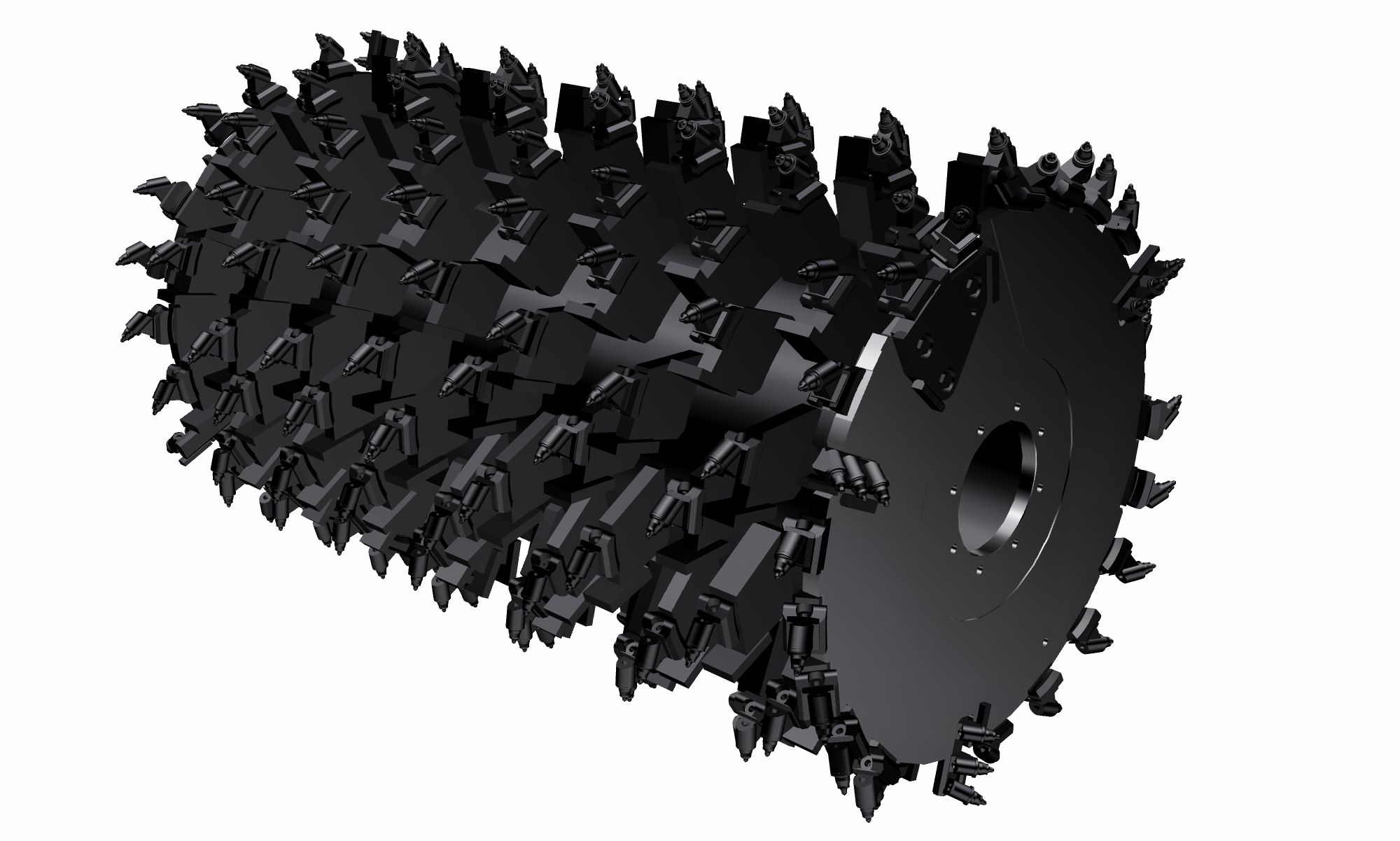

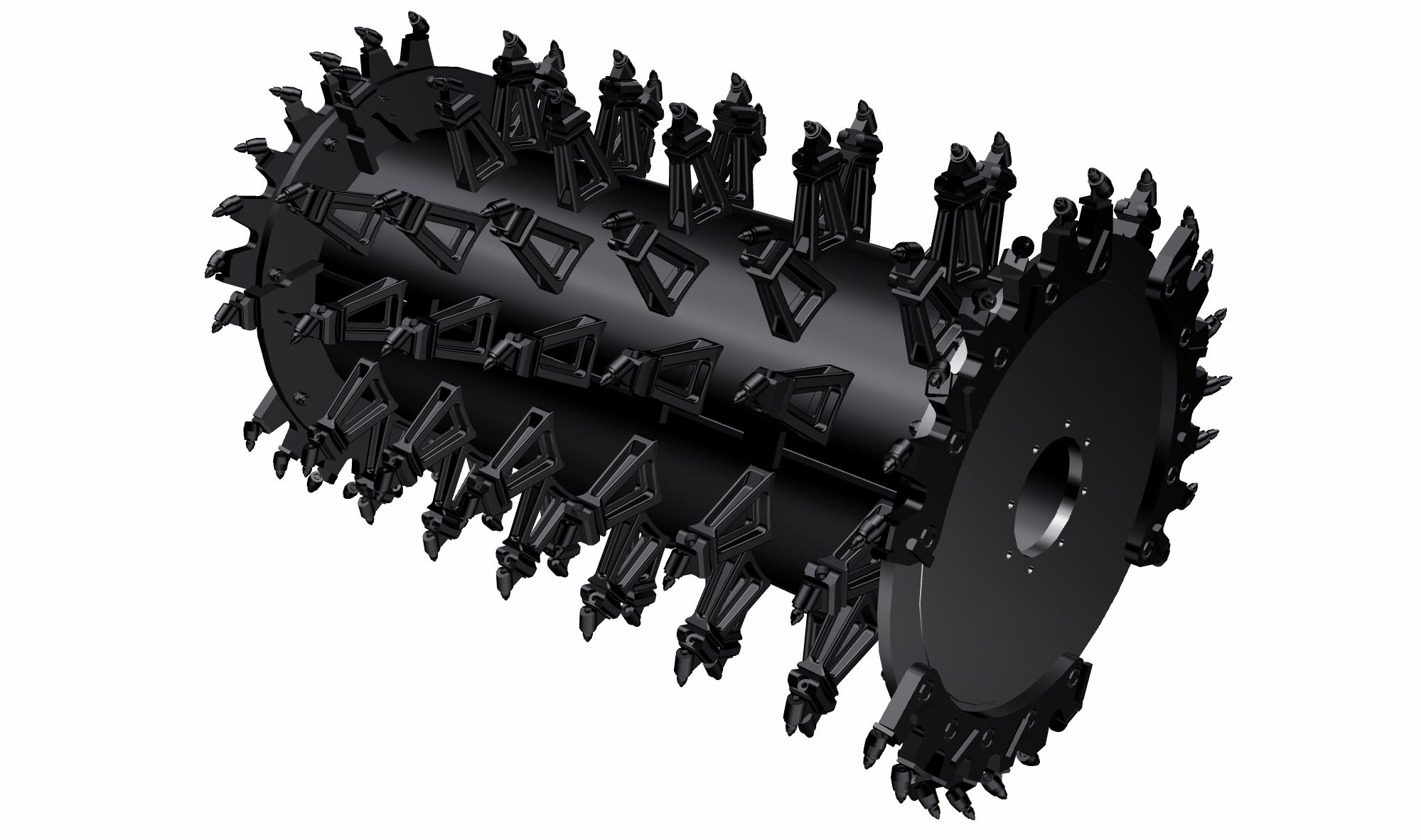

Rotor Options

Universal, Combination, Spade

Rotor Speed - First (at 2100 Engine rpm)

108 r/min

Rotor Speed - Second (at 2100 Engine rpm)

134 r/min

Rotor Speed - Third (at 2100 Engine rpm)

159 r/min

Specification

Value

Gross Power

415.7 HP

Engine Model

Cat C9.3B

Specification

Value

Length

31.4 ft

Width

9.8 ft

Maximum Height

11.5 ft

Wheel Base

20.7 ft

Ground Clearance

19.7 in

Specification

Value

Fuel Tank Capacity

279 gal (US)

- Easily match machine functions with gradation specifications through the 25 cm (10 in) color touch screen displays and push button controls

- Precise machine control is delivered through hand-wheel steering

- Controls are ergonomically located and grouped by function for quick and easy access

- Save time and ensure consistent depth for every cut with automatic features to exit and return to cutting depth

- Keyless push-button engine start can add security and convenience using Operator ID codes to recall saved operator preferences and profiles upon login

- Standard FOPS cab with heating and air conditioning for a comfortable work environment

- Sight lines are optimized with the full left-to-right sliding cab

- A heated, 180º positioning air-ride suspension seat with fore and aft adjustment increases operator comfort and visibility

- Performance and safety can be augmented with standard and optional cameras that are viewed on large, in-cab displays:

- Fore and aft visibility is enhanced with standard front and rear mounted cameras

- Visibility to each side of the machine can be supplemented with optional side mounted cameras

- Obstacle avoidance and gradation results can be viewed with optional cameras mounted above the front and rear mixing chamber doors

- Get 19% more power with the Cat® C9.3B engine that provides

- 310 kW (416 hp) of power and meets regional emission standards

- The overall machine length is 44 cm (17 in) shorter to enhance productivity and maneuverability in compact spaces

- Maximize traction and mobility with standard, electronically controlled all-wheel drive and four steering modes:Front wheels only, rear wheels only, crab steering, and coordinated steering

- Advanced electronic controls deliver ideal mix quality by keeping the rotor at the proper depth and the machine at an optimized speed

- Manage gradation for a wide variety of materials and applications with three separate rotor speeds that can be selected while in operation

- Easily modify material gradation by adjusting the front and rear mixing chamber doors, a simple gauge located on the LCD display keeps the operator informed of door position

- Rear rotor chamber door float feature simplifies operation and allows operator to select desired down pressure

- Work efficiently on a variety of reclamation and stabilization projects with three rotor options: Universal, Combination and Spade

- Water and emulsion additive systems ensure mix design specifications are met

- Application rate of additives is accurately monitored through a computerized metering system

- A wide range of variable flow rates can be optimized for a variety of applications:

- Water flow rates from 30-1900 liters per minute (8-500 gallons per minute)

- Emulsion flow rates from 30-946 liters per minute (8-250 gallons per minute)

- Easily set up the spray system to deliver liquid additives according to specifications: manual or automatic, volume per m2 (yd2) or percent of material density

- Ground level access to routine maintenance items simplifies service and improves safety

- Auto-reversing cooling fan helps prevent debris build-up extending maintenance intervals for cleaning the cooling package

- Rotor drive system utilizes automated bearing lubrication

- Self-lubricating rotor chain drive is adjustment-free and eliminates routine maintenance

- Hydraulically-actuated rotor drive clutch does not require adjustment

- Built-in diagnostics monitor machine systems, alert the operator of performance issues and provide troubleshooting information